Petroleum jelly or Vaseline tests measure the physical and chemical properties of petroleum jelly, such as color, purity, acidity, and flash point.

These tests help us to understand in what industries petroleum jelly can be used, like skincare products, lubricants, and pharmaceuticals.

In this article, you will read the definition and procedures of common petroleum jelly tests.

Penetration or Consistency Test

ASTM D937 (Standard Test Method for Penetration Degree of Petroleum Jelly)

Penetration property, often known as consistency, is a measure of the hardness or softness of petroleum jelly.

In its measurement process, the sample of petroleum jelly is first melted, heated to 82°C (180°F), and then cooled to 25°C (77°F) under controlled conditions.

Then a standard cone (penetrometer) is applied to the sample for 5 seconds under a load of 150 grams. The movement of the penetrometer needle is the penetration value that is reported in the desi-millimeter (d-mm).

Drop Melting Point Test

ASTM D127 (Standard Test Method for Drop Melting Point of Petroleum Jelly)

The drop melting point of petroleum jelly is the temperature at which the material melts enough to drop from the thermometer under certain conditions.

In this test, the ends of two cooled thermometers are dipped in petroleum jelly. Thermometers containing samples are placed in test tubes and heated using a water bath. Until the samples melt and the first drop falls from each thermometer.

The average temperature at which these drops fall, is the drop melting point of the petroleum jelly.

Color Test

ASTM D1500 and IP 17 (Standard Test Methods for color of Petroleum Jelly)

Petroleum jelly can be white, or slightly yellow. High-quality petroleum jelly is often white because it’s been refined to remove impurities.

The IP 17 color test is the Institute of Petroleum standard technique for measuring the color of petroleum products by two methods.

Method A uses Lovibond values, and Method B uses a limited range of 14 color standards known as IP units. The IP units range from Water White (0.25) to Standard White (4.0).

Lovibond values are represented by a set of gradient glasses in red, yellow, blue, and neutral colors.

Petroleum jelly color is in the yellow category of Lovibond values. For example, white petroleum jelly can be displayed as 1Y to 1.5Y in this method.

The ASTM D1500 color test gives numerical values ranging from 0 to 8, where each value represents a color from white to dark red. In this method, white petroleum jelly is identified by 0-1 values.

Watch the video below to see how the ASTM D1500 test is performed.

Kinematic Viscosity Test

ASTM D445 (Standard Test Method for Kinematic Viscosity of Petroleum Jelly)

Kinematic viscosity is a fluid’s resistance to flow under gravity. The test measures the time it takes for a liquid to flow through a viscometer under gravity at a controlled temperature.

The kinematic viscosity obtained from measured flow time multiplied by the calibration constant of the viscometer.

Flash Point Test

ASTM D92 (Standard Test Method for Flash Point of Petroleum Jelly)

The flash point of petroleum jelly is the lowest temperature at which it can create a vapor that may ignite.

In the ASTM D92 test, a cup is filled with about 70 ml of petroleum jelly. At first, the test sample’s temperature rises quickly. As the flash point gets closer, its temperature rises at a slower rate.

In specific time periods, a test flame is passed across the cup. The flash point is the lowest temperature at which the vapors of the test sample ignite.

The ASTM D92 test measures the flash point with the Cleveland Open Cup (COC) tester. Watch the video below to see how this test is done.

Congealing Point Test

ASTM D938 (Standard Test Method for Congealing Point of Petroleum Jelly)

The congealing point is the highest temperature at which a liquid petroleum jelly starts to become semi-solid.

In its measurement test, a sample of petroleum jelly is melted and a droplet is made to adhere to a thermometer.

The droplet on the thermometer is allowed to cool at a fixed rate until it solidifies. The congealing point is observed as the temperature at which the droplet cannot move.

Acidity and Alkalinity Test

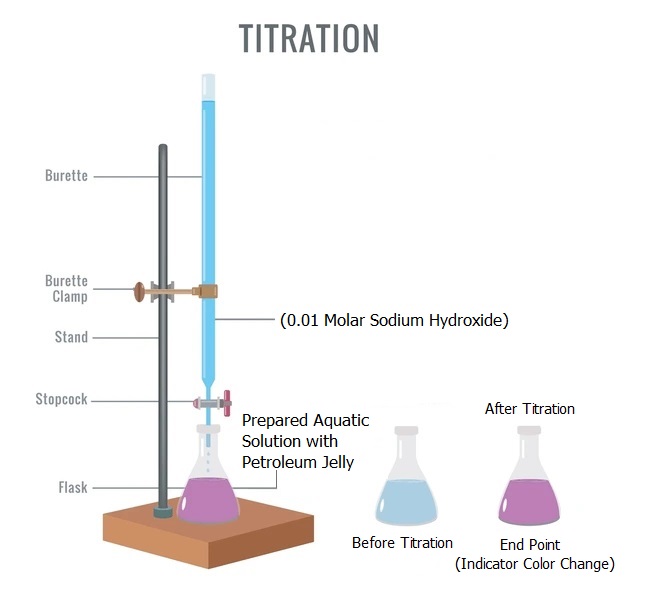

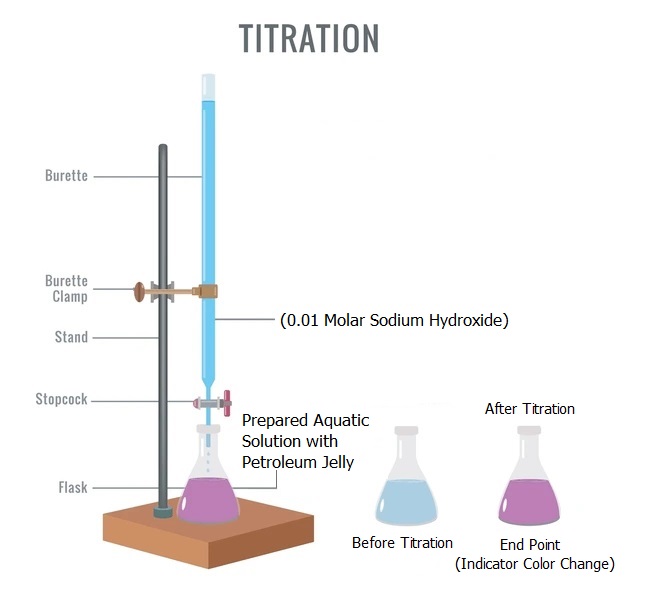

British Pharmacopoeia (BP) 2009 (Standard Test for Acidity and Alkalinity of Petroleum Jelly)

The British Pharmacopoeia (BP) is the official collection of standards for pharmaceutical substances and medicinal products in the United Kingdom that is published annually. The acidity and alkalinity test in BP 2009 standard is as follows:

Add 20 ml of boiling water to 10 grams of petroleum jelly, and shake strongly for 1 minute. After it cools, add 0.1 ml of phenolphthalein to 10 ml of the prepared aquatic solution.

This solution is colorless. Not more than 0.5 ml of 0.01 molar sodium hydroxide is required to change the color of it to pink or red. This process is called titration test. In this case, the petroleum jelly sample passes the acidity and alkalinity standards according to the BP 2009 method.

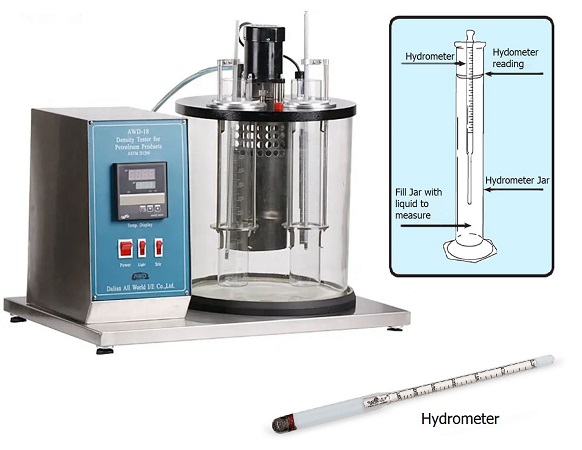

Density Test

ASTM D1298 (Standard Test Method for Density of Petroleum Jelly)

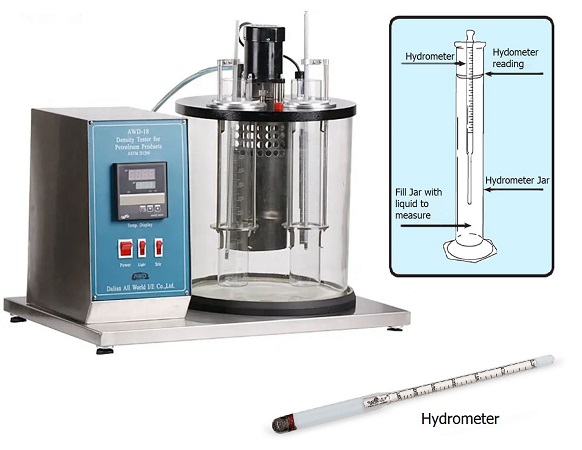

Density is a physical property that indicates the degree to which the particles of a material are packed closely together. It can be calculated by dividing the material’s mass by its volume.

In the ASTM D1298 test, at a certain temperature and using a hydrometer, the density of petroleum jelly is determined. A hydrometer is a tool that measures the density, or specific gravity, of a liquid.

Polycyclic aromatic hydrocarbons (PAHs) Test

British Pharmacopoeia (BP) 2009 (Standard Test Method for PAHs of Petroleum Jelly)

Polycyclic aromatic hydrocarbons (PAHs) are a class of organic compounds that are naturally in petroleum products.

Ideally, the refining process removes PAHs from petroleum jelly. Based on the BP standard, the amount of PAHs in petroleum jelly should be less than 300 ppm.

In the 2009 BP report, the following method is determined to measure the amount of PAHs:

In this method, 1g of petroleum jelly is placed in several stages of liquid-liquid extraction with hexane and dimethyl sulfoxide. And the absorbance of one of the extraction products (as a test solution) is measured in the range of 260 nm to 420 nm by UV-Vis Spectrophotometer .

The reference solution is 6 mg/L of naphthalene (the simplest PAH) in dimethyl sulfoxide. It was used to measure the maximum absorbance at 278 nm.

The absorption of the test solution in the wavelength range of 260 nm to 420 nm should not be more than the absorption of the reference solution.

Sulfated Ash Test

British Pharmacopoeia (BP) 2009 (Standard Test Method for Sulfated Ash of Petroleum Jelly)

Ignite a suitable crucible (for example silica, platinum, or quartz) at 550 °C to 650 °C for 30 minutes, cool the crucible in a desiccator and weigh it accurately.

The determined amount (2 grams) of petroleum jelly is placed in a suitable container and weighed. The substance is moistened with a small amount of sulfuric acid (usually 1 ml) and heated slowly at a temperature as low as possible until the sample is completely burned.

After cooling, the residue is moistened with a small amount of sulfuric acid (usually 1 ml). The prepared mixture is slowly heated until no more white vapor is produced. Then it ignited at 600 ± 50 °C until the residue completely burned.

Ensure that a flame is not created at any time during the operation. After cooling, weigh the residue again and calculate the percentage of the residue. The percentage of sulfated ash should be less than 0.05%.

If you have any questions, leave a comment for us. We will be happy to read your ideas and opinions related to this article.