Petroleum jelly, also known as petrolatum and vaseline, is made of mineral waxes and oils. Understanding the production process of petroleum jelly can give information on its quality and purity.

The petroleum jelly manufacturing process can be explained in three steps:

- Blending of Wax and Oils

- Hydrotreating

- Filtration

Continue reading this article to learn more details about each step of the petroleum jelly production process.

How is Petroleum Jelly Made?

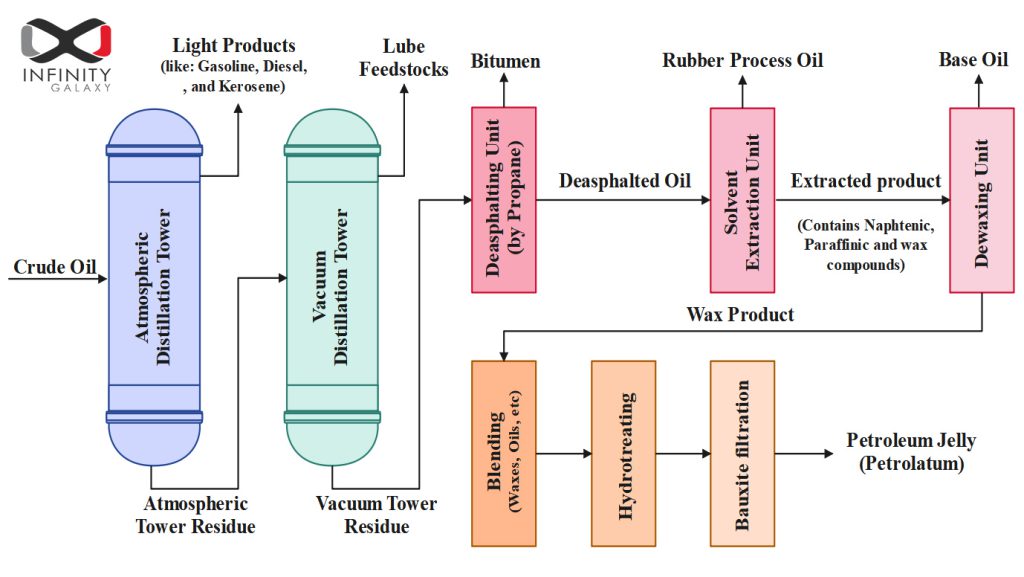

Mineral waxes and oils, the main ingredients of petroleum jelly, are byproducts of crude oil refining. Paraffin wax or the mixture of it with microcrystalline wax are used for petroleum jelly production.

Another component of petroleum jelly is high-quality base oils, either synthetic or mineral. Instead of mineral oils, vegetable oils may be used; however, mineral oils are more stable and more resistant to oxidation and rancidity. As a result, they don’t cause allergies, in contrast to vegetable oils.

The following flowchart shows the procedures used to make base oil and paraffin wax. After the dewaxing unit separates base oil and paraffin wax, they are employed for the petroleum jelly production process in the next steps.

Blending of Wax and Oil

In this step, different amounts of waxes and oils are mixed together to produce various types of petrolatums. Vegetable oils, mineral and synthetic base oils or other types of mineral waxes could be added in the mixture for desired properties of petroleum jelly.

It’s clear that petroleum jelly with high wax content has higher melting points and a harder consistency, while those with high oil content are softer and more fluid. So the mixing of oils and waxes should be according to specific needs.

If you are interested in knowing how the properties of petrolatum are measured see the vaseline petroleum jelly Test post.

Hydrotreating

The hydrotreating process removes all of the impurities like sulfur, nitrogen, and metals by using a high volume of hydrogen. It also saturates the hydrocarbon bonds and increases the final product’s stability.

Bauxite Filtration

The petroleum jelly is filtered through bauxite to eliminate its odor, color, and taste. It has been discovered that petrolatum can be decolorized and deodorized in a single stage of filtration.

This process involves passing a liquid petroleum jelly at temperatures ranging from 130°F to 400°F through activated bauxite at pressures greater than atmospheric pressure.

The activated bauxite acts as a highly effective adsorbent, removing impurities and leaving behind a purer form of petroleum jelly. This filtration process results in a white petroleum jelly with the lowest impurities.

We hope you found this article enjoyable and informative. Keep in touch with us for any questions or inquiries in the comment box.