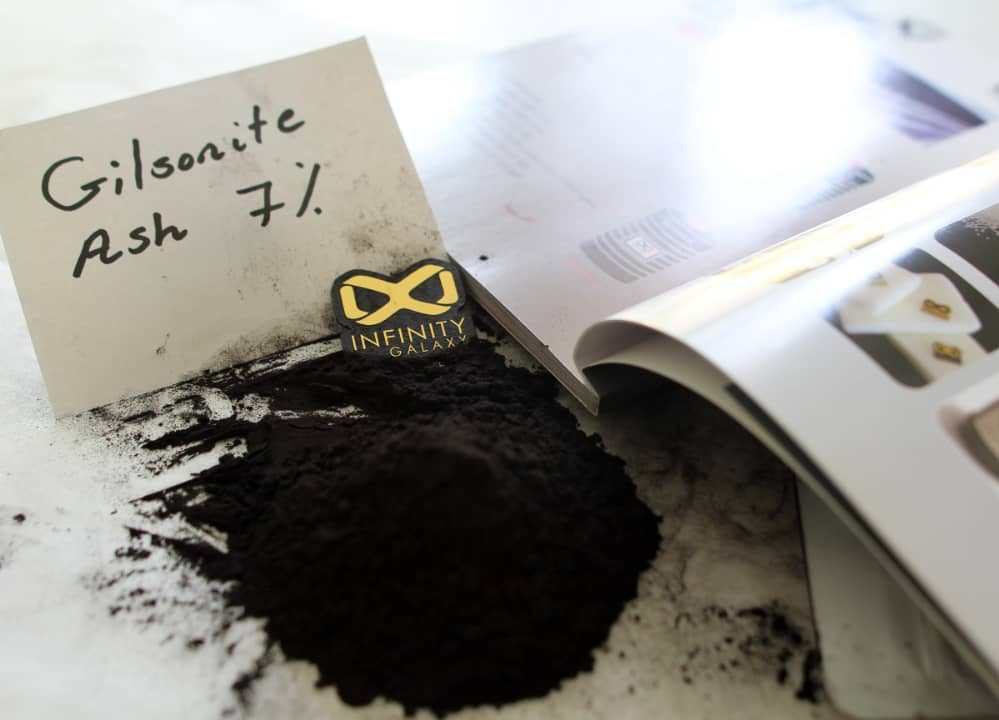

Gilsonite is the natural bitumen that can be extracted from the mines in the lump form with different ash content.

These lumps can be used in the same form in industry. But, for easier and faster progress in work, it can also be used as a micronized powder. Infinity Galaxy as an international bitumen supplier provides gilsonite in both lump and micronized powder based on the customer’s order.

Generally speaking, gilsonite has various applications, but the main usages of this bitumen is in the road construction, drilling mud and printing industry.

To get more information about Gilsonite, stay tuned.

The Production Process of Micronized Gilsonite Powder

First, the gilsonite lumps are extracted from mines and transferred to the factory in different irregular dimensions. These lumps are crushed by a hopper. Then they enter to the different mills and convert to the smaller portions to reach the desired mesh size and become micronized. The larger the mesh size, the finer the grains.

Different Types of Micronized Gilsonite Powder

There are different types of micronized gilsonite powder based on the percentage of ash content and mesh size. Infinity Galaxy supplies the micronized gilsonite powder with less than:

- 5% ash content

- 10 % ash content

- 15% ash content

- 20% ash content

In addition to the percentage of ash content, mesh size plays a significant role in classification of gilsonite.

Mesh is a standard measurement of particle size and granulation of powder. According to the US standard, ASTM E-11, we have various mesh numbers from 35 to 635 (500 to 20 micron). Many of Infinity Galaxy customers order the micronized powder with the 200 mesh which is equal to 74 micron.

The Application of Gilsonite

Gilsonite can be used in the vast majority of industries. You can see the three main applications of this material below:

Road Construction: It can be used in asphalt and road construction. The use of gilsonite in hot asphalt mixtures is very common. Gilsonite is a suitable modifier for the bitumen in asphalt.

Mixing it with bitumen increases the strength and resistance of pavements to traffic, reduces the effect of wheels on pavement cracks at low temperatures, and prevents deformation of asphalt in hot weather. It can also avoid the effects of moisture on hot asphalt mixes.

Drilling Engineering: It is a good choice as an additive for drilling fluids since it increases wellbore stability and controls the loss of drilling mud.

Printing industry: the most important raw materials of printing inks are carbon black and gilsonite. It is a cost effective replacement for other resins that are used in printing ink.

In addition to the above applications, Gilsonite can be used in painting, coating, cable industry, construction insulation industry, cosmetic and rubber industry.

Also, metallurgical engineers can use this material in casting. After processing this bitumen, it can also be used in pharmaceutical industries.

| Specifications of Gilsonite in Different Applications | ||||||

|---|---|---|---|---|---|---|

| Specifications | Test Method | Drilling | Asphalt & Road | Isolation | Paint & Ink | Foundry |

| Ash Content, WT% | ASTM D3174 | 7-13 | 10-15 | 10-20 | 7-10 | 10 |

| Mesh Size | ASTM D546 | 200 | 100-200 | 100 | 200 | 100-200 |

| Moisture Contentment, WT% | ASTM D3173 | 1-3 | 1-3 | 1-3 | 1-3 | 1-3 |

| Volatile Matter, WT% | ASTM D3175 | 65-85 | 65-85 | 65-85 | 65-85 | 65-85 |

| Solubility in CS2,WT% | ASTM D4 | 75-85 | 70-80 | 70-80 | 80-90 | 75-85 |

| Specific Gravity, at 25 °C | ASTM D3289 | 1.05 | 1.05 | 1.05 | 1.05 | 1.05 |

| Color | – | Black | Black | Black | Black | Black |

| Softening Point | ASTM D36 | 180-220 | 180-220 | 180-220 | 180-220 | 180-220 |

The Benefits of Gilsonite

- Excellent adherence

- Long durability

- High resistance in environments with very high temperature

Factors Affecting the Price of Gilsonite

- Percentage of ash content

- Mesh size

- Percentage of solubility

- Percentage of carbon

- Moisture of bitumen

- Being powder or lump

- Gilsonite packaging

- Order season

During the rainy season, the natural bitumen mines are mostly closed and there is no ability to move the bitumen from the mine to the packing place or depot, so the cargo in the warehouse is sold more expensively.

The Quality of Gilsonite

Some of the factors above are too important in evaluating the quality of gilsonite.

One of them is solubility of the bitumen. The higher the solubility, the better the quality. Generally speaking, gilsonite solubility varies in different solvents but is soluble in most petroleum products.

Another factor is the percentage of ash content. The lower the amount of ash in gilsonite, the higher the quality of the bitumen.

The third important factor in gilsonite micronized powder quality is the meshing. The larger the mesh, the smaller the fines and particles size, so the better the quality of the powder.

The packing of Gilsonite

- Kraft bag on the pallet

- AD Star bag on the pallet

- AD Star bag in the jumbo bag that can be placed on a pallet

- Micronized Powder in the jumbo bag

- Ordinary bags with the capacity of 25 Kg that can be placed on a pallet

- Ordinary bags with the capacity of 25 Kg in the jumbo bag that can be placed on a pallet

Read More about Bitumen Packages

Infinity Galaxy, the International Gilsonite Supplier

Infinity Galaxy provides high quality gilsonite from valuable mines in the Middle East. Our specialists at Infinity Galaxy will help you easily get the Gilsonite you need in your desired packaging at a suitable price.

To get more information about Gilsonite, you can Contact us or fill out the below inquiry form.