Major applications of bitumen emulsion are in road construction works, such as soil stabilization and sticking asphalt layers well together. Also, it is used for the improvement of old asphalt surfaces by filling cracks and insulation.

Bitumen emulsion is effective in insulation and waterproofing application besides road construction.

In this article, the application of emulsion bitumen in road construction and repair works will be discussed. You also learn about factors affecting the bitumen emulsions selection.

Applications of Bitumen Emulsion in Repairing and Maintaining Road Surface

One of the important applications of bitumen emulsion is in repairing and protecting asphalt pavement surfaces. Bitumen emulsion and aggregates are applied to the surface with different methods which are known as protective asphalt.

Protective asphalt prevents surface erosion which is caused by traffic. It also helps to reduce the cracked surface caused by temperature changes.

Moreover, it limits water penetration into sub-layers.

Choosing a proper method is a significant issue. If the steps of the repair or maintenance method are done correctly, the layers’ structure will have high quality.

As a result, asphalt with long-lasting life will be made while it has a low implementation cost and a simple operation.

Below are the cases where bitumen emulsion is used for repairing asphalt pavement surface and maintaining it:

- When the asphalt bitumen has aged and caused cracks in the asphalt surface.

During the aging, bitumen dries out and its adhesive properties decrease.

In this case, a protective layer can be used.

- The surface of a new asphalt pavement can be protected by a thin asphalt layer made up of bitumen emulsion and aggregates. Also, it insults the lower layers from water penetration.

- The bitumen binder may leak out of the space between the aggregates due to weather conditions or non-standard road construction.

Also, high traffic may erode the aggregates used in the asphalt. Therefore, the surface of the asphalt has been smooth.

In such situations, the surface can be improved with emulsion bitumen along with sharp and rough aggregates.

- Asphalt surface layers that have weathered, reach proper performance by creating one or more layers of protective asphalt.

Sometimes road construction may be stopped and all final layers may not be built.

Creating a temporary protective layer is a suitable cover for a fresh base layer of pavement in winter. Because the double seal coat provides a very suitable temporary layer before the final asphalt layer is applied.

The following include types of surface repair (or protective asphalt) methods using bitumen emulsion. Each of them pursues one or more specific goals:

Seal Coat:

In seal-coating, bitumen emulsion is applied to the surface of existing old asphalt, after which aggregates are poured and rolled.

The purpose of a seal coat is to cover the old asphalt surface cracks and damages. Also, it can waterproof the asphalt surface.

A seal coat should be applied to asphalt periodically to increase its efficiency and reduce reconstruction costs.

These grades are proper for it: CSS-1, CSS-1h, SS-1, and SS-1h

Chip seal:

Chip seal consists of applying a layer of aggregates and rolling it on the surface covered by bitumen emulsion. It is applied in 2 or even 3 layers on an old asphalt surface and this is the main factor that separates it from the Seal coat.

Chip seal is used to improve skid resistance and surface sealing.

CRS-2 and RS-2 are suitable grades of bitumen emulsion for applying chip seals.

Seal Coat Sandwich:

This is a new method of coating. Seal coat involves spreading coarser grains on the surface first, then applying emulsion bitumen, followed by finer grains.

Bitumen emulsion grades that can make seal coat sandwiches are CRS-2 and RS-2.

Cape seal:

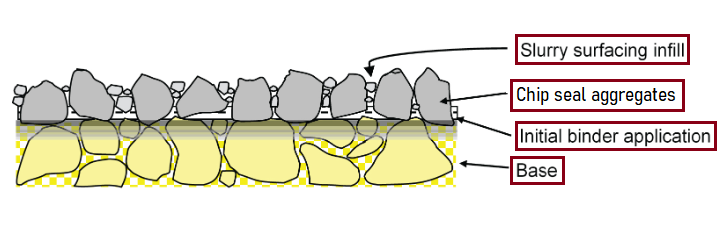

A cape seal consists of two layers, a chip seal and a slurry seal.

Chip seal is applied first as a repair surface. A layer of slurry seal or micro-surfacing is done on the chip seal. This layer fills the space between the aggregates and increases the friction of the road surface.

Cape seals usually have more friction than normal asphalt. This layer can be used for roads that have a higher wear rate as a result of high traffic to increase the life of the road.

The grades of bitumen emulsion that can be used in cape seal are CSS-1h, SS-1h, RS-2, and CRS-2.

Slurry Seal:

The slurry seal contains a high amount of very small crushed rock which is combined with emulsion bitumen, filler, additives, and water.

It is applied on the damaged asphalt and in addition to sealing the surface, it prevents asphalt from moving.

For applying a slurry seal on a road CSS-1, CSS-1h, and SS-1 are used.

Microsurfacing:

Microsurfacing is similar to a slurry seal, but it is more durable and can be used in greater thicknesses because it is made from polymers.

It is used for sealing, increasing friction, and filling cracks up to 3 centimeters deep.

In this method, CSS-1h and polymer bitumen are used.

Emulsion Bitumen Application Based on the Setting Time

1- Rapid Setting Emulsions

In these bitumen emulsions, the bitumen separates from the water very fast. As a result, it is used for sealing like chip seal, sand seal, and surface repairs.

Their viscous types are used for fast adhesion on roads with heavy traffic, as well as roads with low quality control or heavy traffic of vehicles.

2- Medium Setting Emulsions

Medium setting types are used to combine with all types of aggregates since their emulsion does not break quickly after contact with the stone surface.

Medium setting time types are used in cold asphalt recycling stages. If combined with polymers, they will have higher viscosity. Viscose types are used where more water resistance is required.

3- Slow Setting Emulsion

Slow setting bitumen emulsion is used for the stability of mixtures. It is used with stone materials with high density and many fine particles.

This type of bitumen is not designed for mass storage.

By diluting the slow setting emulsion bitumen, it can be used for single coats and fog seals.

Applications of Bitumen Emulsion in Road Construction

One of the most common uses of bitumen emulsion is in road construction.

Asphalt consists of three layers, which are bonded together by emulsion bitumen layers. They are called tack coat and prime coat.

For more information about the bitumen emulsion of these layers, read the article “Different Types of Bitumen in Asphalt Layers”.

Application of Emulsion Bitumen in Dust Suppression

Driving on dirt roads creates dust. Sometimes, the lack of cost and also low traffic lead to the use of diluted bitumen emulsion instead of asphalt.

To suppress dust, slow setting cationic or anionic emulsions are used.

They should be diluted 5 times or more by mixing with water and then sprayed on soil areas.

What is the Spreading Temperature of Each Type of Bitumen Emulsion for Road Construction?

The temperature of applying bitumen emulsion to surfaces is very important. Because, if the temperature of the application rises above 100 degrees, the water content decreases.

By reducing the percentage of water, bitumen emulsion becomes more viscous. High-viscosity emulsion bitumen spreads less because it cannot create a thin coating on aggregate surfaces.

Therefore, bitumen and aggregates cannot be combined uniformly. Bitumen coating levels vary wildly in some areas and in others, which causes many problems. For example, increases in the amount of binder bitumen came out from the asphalt surface etc.

The table below shows a summary of the appropriate temperature range for applying the desired grade of emulsion bitumen.

| Bitumen Emulsion | Spreading Temperature (C) | Bitumen Emulsion | Spreading Temperature (C) |

| RS-1 | 20-60 | SS-1 | 20-70 |

| RS-2 | 50-85 | SS-1h | 20-70 |

| MS-1 | 20-70 | CRS-1 | 50-85 |

| MS-2 | 20-70 | CMS-2h | 20-70 |

| MS-2h | 20-70 | CSS-1 | 20-70 |

| CSS-1h | 20-70 |