The viscosity test of bitumen measures the bitumen viscosity. This property shows how easily bitumen flows.

The higher the viscosity of the bitumen, the harder it is to flow. Consequently, it behaves more like semi-solid matter.

Bitumen viscosity is determined by viscometers. In the following video, our team at Infinity Galaxy shows how rotary and capillary viscometers are used to measure dynamic (ASTM D4402) and kinematic (ASTM D2170 or IS 1206) viscosity of bitumen.

Below is a list of different ways of specifying viscosity and measuring it based on the Indian bureau standard definition:

- Industrial viscosity => The dynamic viscosity which is measured by the cup viscometer is called industrial.

- Dynamic/Absolute viscosity => It is measured by different types of vacuum capillary viscometers.

- Kinematic viscosity => It is measured by different types of capillary viscometers.

In general, to perform the viscosity test of bitumen, the sample is placed in the viscometer then the flow-out time of bitumen is measured under specified conditions. Finally, the amount of viscosity is determined by multiplying the calibration coefficient of the viscometer by the flow time in seconds. The bitumen viscosity unit is based on mm2/s [cSt].

Here is an example of the viscosity value of viscosity bitumen grades based on IS 1206 method parts II and III:

| Viscosity Value of Viscosity Bitumen Grades | ||

|---|---|---|

| Paving Grades | Absolute Viscosity @ 60 °C, Poises | Kinematic Viscosity @ 135 °C, CSt |

| VG 10 | 800 – 1200 | 250 |

| VG 20 | 1600-2400 | 300 |

| VG 30 | 2400 – 3600 | 350 |

| VG 40 | 3200 – 4800 | 400 |

Table of Contents

Why Do We Use the Viscosity Test of Bitumen?

The aim of standard construction is to have a uniform and stable asphalt. This is gained when the aggregates are well-packed and the space between them is filled well. Viscosity is a good property to show the ability of bitumen in coating and adhesion.

Low viscosity bitumen tends to flow and behave like a lubricant and not a binder, so it cannot adhere to aggregates well.

Moreover, compacting aggregates is difficult with a high viscosity bitumen binder thus, asphalt will not be uniform. Consequently, it is important to choose a bitumen with a suitable viscosity.

Viscosity is a property that is affected by temperature changes. For this reason, engineers measure the viscosity of bitumen at two different temperatures of 60 °C and 135 °C. As a result, we can predict the best temperature that bitumen should mix and compact.

Absolute or dynamic viscosity at 60 °C is measured to indicate the resistance of bitumen to melting and flow.

Also, this test can be a substitute for the softening point test. Because the softening point test is directly related to the viscosity property. Furthermore, it measures the resistance of bitumen to melt and flow.

At higher temperatures, bitumen viscosity measurements are necessary to better understand its ability to coat aggregates well. Therefore, the kinematic viscosity is measured at 135 °C.

Different Methods for Viscosity Test of Bitumen in International Standards

The following standard methods can be used to determine the viscosity of bitumen:

- Industrial viscosity

- IS 1206 (I)

- EN 12846-1

- EN 12846-2

- Absolute or dynamic viscosity

- ASTM D2171

- ASTM D4402

- AASHTO T202-03

- AASHTO T316-06

- EN 12596 dynamic at 60

- EN 13302

- IS 1206 (II)

- Kinematic viscosity

- ASTM D2170

- ASTM D2161

- ASTM D445

- AASHTO T201-03

- EN 12595 kinematic at 135

- IS 1206 (III)

- IP 543

Industrial, dynamic, and kinematic viscosity tests according to IS 1206 method I, II, and III are described as follows:

Viscosity Test of Bitumen Based on IS 1206

The component of the apparatus and the test method of different types of bitumen viscosity are described below based on IS 1206 parts I, II, and III:

1. Industrial Viscosity Test of Bitumen

An industrial viscosity is defined as a fluid’s ability to resist flow. It is measured by a cup viscometer.

Cup viscometer usually measures the viscosity of bitumen emulsions, but it also measures the viscosity of tar and cutback bitumen. A cup viscometer can be classified into various types according to the size of the drain hole (orifice).

The cup viscometer is used to determine the time in seconds that it takes for 50 ml of bitumen to flow through an orifice in a specific size at a specific temperature. In the next step, the viscosity value is determined by multiplying the time in the calibration coefficient of the viscometer.

1.1. The Equipment to Measure the Industrial Viscosity

The following equipment will be required:

- Tar viscometer

- Cup

- Water bath

- Stirrer

- A measuring cylinder

- Stopwatch

- Thermometer

1.2. The Procedure of the Industrial Viscometer Test

In the first step place the tar viscometer in the cup. Make sure the top surface of the cup is level. Heat the water bath to the test temperature and keep it constant during the test. The stirrer should be gently stirred.

The bitumen sample should be heated by about 20 °C over the temperature stated in the test. The bitumen sample must be cooled to the specified testing temperature. Pour the specimen into the cup until the leveling peg on the valve is just submerged. The valve rod should remain vertical during this process.

Clean the orifice with a suitable solvent. Pour 20 ml of mineral oil or 1 % by weight solution of soft soap in the graduated cylinder which is placed under the orifice of the cup.

Place the thermometer in the cup. Keep stirring until the tar reaches the test temperature. The thermometer should be positioned in the center of the tar, parallel with the cup. For 5 minutes, let the apparatus stand. During this time, the thermometer reading should remain within 0.05 °C of the specified test temperature. Remove the thermometer. Also, be sure to remove any excess samples as soon as possible. Ensure that the level of bitumen is on the center of the leveling peg when the valve is vertical. Suspend the valve on the valve support.

Start the stopwatch when the cylinder reads 25 ml. Then stop it when the cylinder reading reaches 75 ml and note the time in seconds.

The test should be repeated several times with the same material. The mean value of recorded times is the final result.

Note that for repeated measurements, if the mean value of viscosity is less than 40 seconds the highest and lowest values should not differ more than ±2 seconds. Also, for the average value of more than 40 seconds, the highest and lowest values should not differ more than ±5 % of the mean value.

2- Dynamic or Absolute Viscosity Test of Bitumen

Dynamic viscosity, also called absolute viscosity, is the internal resistance between moving fluid layers caused by the adhesions of the fluid’s molecules.

It is measured by a vacuum capillary viscometer. To measure the viscosity, a capillary (very thin) tube is placed in the water bath. The temperature of the water bath can be both 60 °C or 135 °C.

The time that takes to pass bitumen through the capillary tube is recorded. Viscosity is obtained by multiplying the time with the calibration coefficient.

2.1. Equipment to Measure the Dynamic or Absolute Viscosity:

The following equipment will be required:

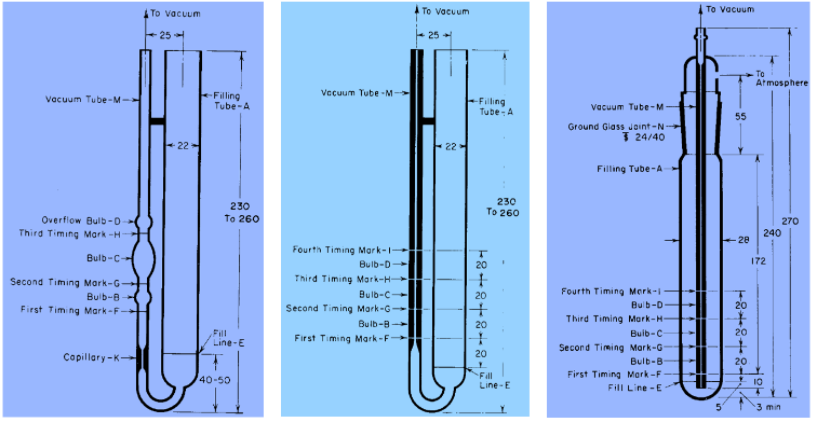

- Capillary viscometer:

- Cannon-manning vacuum capillary viscometer

- Asphalt institute vacuum capillary viscometer

- Modified Koppers vacuum capillary viscometer

- Water bath

- Thermometer

- Vacuum pump

- Oven

- Stopwatch

- Stirrer

2.2. The Procedure of Dynamic Viscosity Test of Bitumen:

Heat the sample above its approximate softening point temperature until it has become sufficiently fluid to pour. For tar and bitumen samples the temperature should not be more than 60 °C and 90 °C respectively.

Fill the viscometer with the sample to line E. Put the viscometer in the oven or in a paraffin bath maintained at 135 °C for a few minutes until the air bubbles disappear.

Place the viscometer filled with samples vertically in the water bath maintained at the test temperature. Using a vacuum pump, create a vacuum of 40 kPa under atmospheric pressure and connect the device to the viscometer. Open the valve after 30 minutes and let the bitumen sample flow through the viscometer. Record the time that bitumen passes between pairs of timing marks. Note that the time is more than 60 seconds.

The value of viscosity is obtained by multiplying the recorded time by the calibration coefficient of the viscometer.

3- Kinematic Viscosity Test of Bitumen

Kinematic viscosity is the ratio of the dynamic viscosity of a fluid to its density (mass to volume ratio).

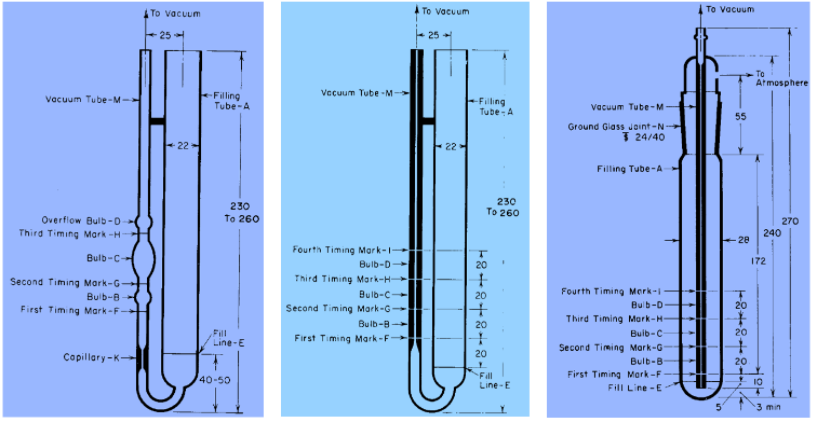

A capillary viscometer is used to measure kinematic viscosity. There are two different types of it:

- Cannon-Fenske Viscometer (for Opaque liquids)

- BS U-Tube Modified Reverse-flow Viscometer

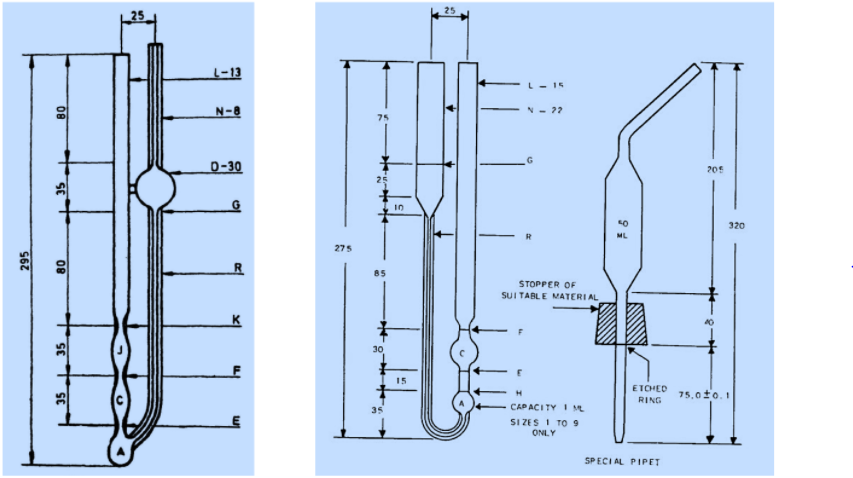

Figure 4: (a) Cannon-Fenske Viscometer (for Opaque liquids) (b) BS U-Tube Modified Reverse-flow Viscometer

3.1. Equipment to Measure the Kinematic Viscosity:

The following equipment will be required:

- Viscometer

- Water bath

- Thermometer

- Oven

- Stopwatch

- Stirrer

3.2. The Procedure of Kinematic Viscosity Test of Bitumen:

-Sample Preparation:

- Cutback bitumen: Stir the cutback sample into the container until it is thoroughly mixed. Be careful not to trap air bubbles when stirring. If the sample is very viscous, it is better to heat it to 60 °C and then transfer 20 ml to a container with a volume of 30 ml.

- Bitumen: Heat the sample until it becomes a uniform liquid. The temperature required for heating should be above the softening point. Also, when heating, the temperature of the tar and bitumen sample should not be higher than 60 °C and 90 °C, respectively. Finally, transfer 20 ml of the sample to a 30 ml container.

-The Procedure of Kinematic Viscosity Test of Bitumen

- Cannon-Fenske Viscometer (for Opaque liquids)

Fill the Cannon-Fenske viscometer by inverting it and applying suction to tube L. Immerse tube N in the liquid sample. Pour liquid through tube N, filling bulbs D until mark G is full. Remove excess sample of tube N. Invert the viscometer to its normal position. The viscometer should be positioned vertically in the bath.

The viscometer should remain in the water bath until the bitumen sample reaches the test temperature. Then remove the stopper in tubes N and L respectively and let the sample flow down by gravity.

Finally, measure the time required for bitumen to pass from timing mark E to timing mark F. Select a viscometer with a smaller capillary diameter if this efflux time is less than 60 s.

- BS U-Tube Modified Reverse-Flow Viscometer

Install the BS U-tube viscometer vertically in the constant temperature bath. Pour sample through tube N to a point just above filling mark G. Let the sample flow freely through capillary R. Take care that the liquid column remains unbroken until the lower mark H. Then stop its flow by closing the timing tube with a stopper in tube L.

Let the sample reach room temperature and the air bubbles trapped in the bitumen slowly rise up and the specimen empty from the air bubble.

Remove the stopper and let the sample flow. Until it is approximately at the lower filling mark H then press back the stopper to stop the flow.

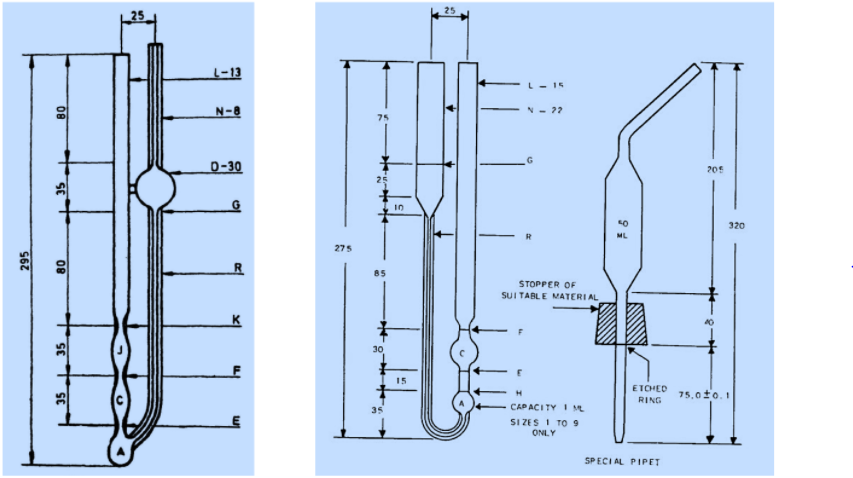

The excess sample above filling mark G must be removed. This can be possible by inserting the special pipette until its stopper reaches at top of tube N. Then apply gentle suction until the air is drawn through. The top level of the sample shall coincide with mark G.

For the sample to reach temperature equilibrium, the viscometer must be in the constant temperature bath for a sufficient time.

After that, remove the stoppers from tubes N and L and let the sample flow down by gravity. Measure the time required to pass bitumen from timing mark E to timing mark F. Select a viscometer with a smaller capillary diameter if this efflux time is less than 60 s.