Bitumen is a complex material that does not have a distinct melting point. As the temperature rises, the bitumen gradually softens and its viscosity decreases therefore the softening point is defined.

What is the softening point of bitumen? The softening point of bitumen is the temperature at which the bitumen softens beyond some arbitrary softness. It can be determined by the softening point test.

You can watch the video below to learn about the softening point test of bitumen and its steps.

Ring and Ball Test

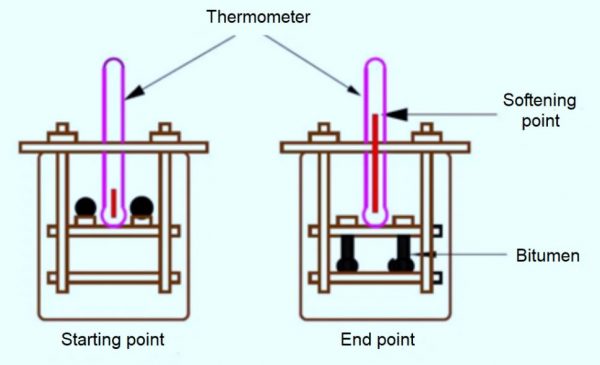

The laboratory method of measuring the softening point is the ring and ball test. In this test, the bitumen sample is taken in two brass rings and steel balls are placed on it. The system is placed in a water bath and heated. The temperature at which a steel ball with a bitumen coating hits the bottom of a glass beaker is called the softening point temperature.

The softening point of smooth native asphalt, road bitumen, coal bitumen, and blown bitumen can be measured by ring and ball apparatus. Hard bitumen and oxidized (blown) bitumen are specified by softening point and penetration test.

In general, with higher the softening point, the lower the temperature susceptibility. In other words, the thermal resistance is higher.

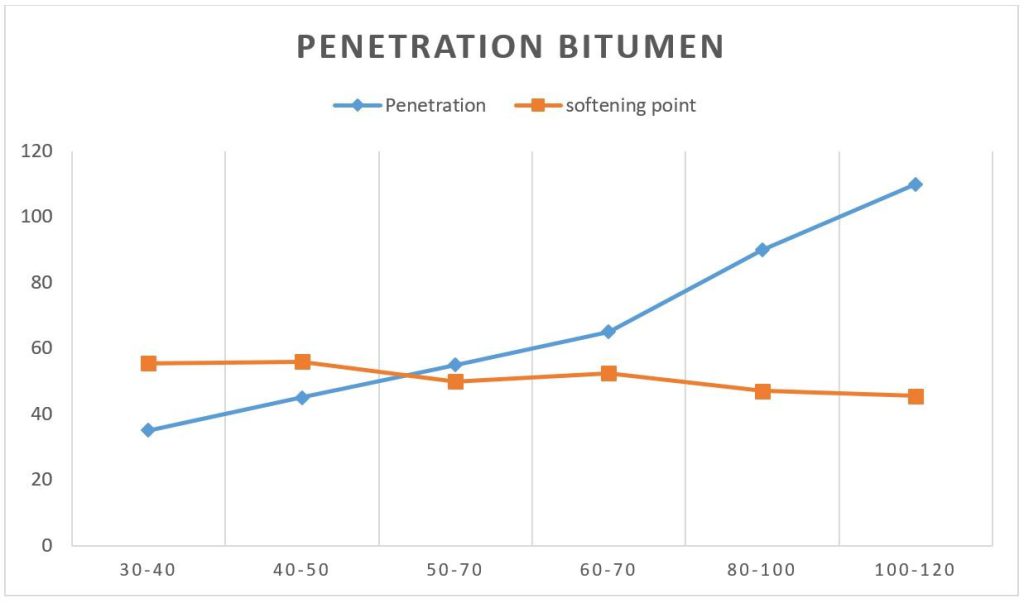

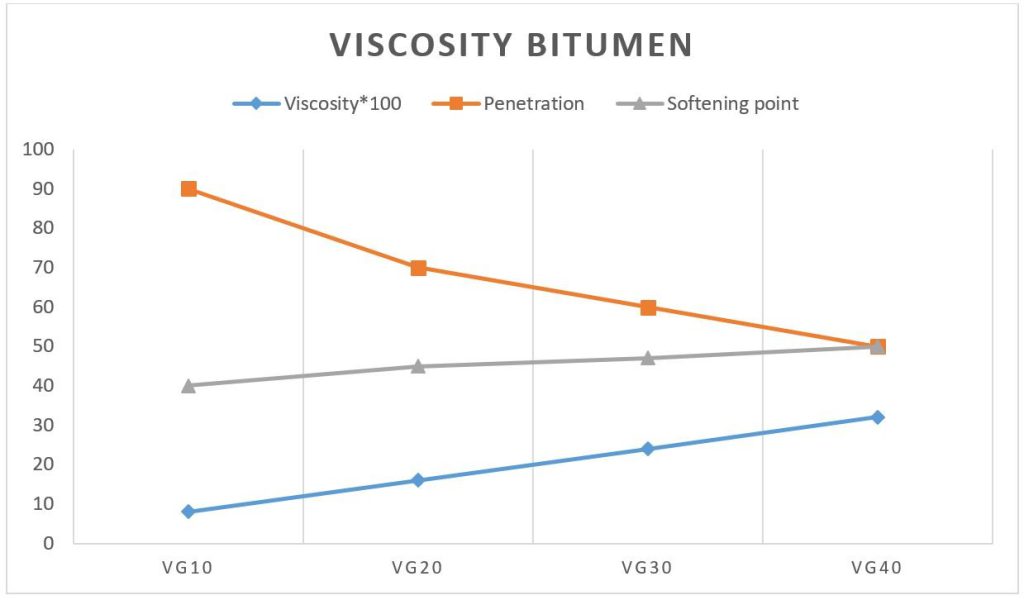

Here is an example of softening point of viscosity bitumen grades based on the Indian bureau standard method (IS 1205) :

| Softening Point of Viscosity Bitumen | |

|---|---|

| Grades | Softening Point ( °C) |

| VG 10 | 40 °C |

| VG 20 | 45 °C |

| VG 30 | 47 °C |

| VG 40 | 50 °C |

Why do We Use a Softening Point Test of Bitumen?

Softening point test specified bitumen based on its temperature resistance which indicates the proper bitumen binder in the desired weather conditions when constructing roads.

In areas with hot weather, bitumen should be more resistant to high temperatures, so a higher softening point bitumen is used. In other words, the softening point value should be higher than pavement temperature, otherwise, bitumen present in the layer will be soft and sticky.

On the contrary, low temperature-resistant bitumen is used in moderate to cold climates.

Check out the article about “different types of bitumen in road construction” if you’re interested.

The Relationship Between Bitumen Penetration and Softening Point

In general, the softening point of penetration grade bitumen and viscosity grade bitumen decreases as penetration increases. In fact, softer bitumen gradually melts at lower temperatures, and its thermal resistance is lower.

Softening point increases with viscosity as well. This means that viscous bitumen starts to soften at higher temperatures. As a result, the temperature susceptibility decreases with increasing viscosity.

To learn more about the viscosity test of bitumen, click here.

To learn more about bitumen penetration testing, click here.

In oxidized(blown) bitumen, there isn’t a clear relationship between the softening point and the degree of penetration. It depends on the method of production.

Read the different ways of bitumen production.

In this type of bitumen, the amount of softening point is more than viscosity grade bitumen and penetration bitumen. Consequently, oxidized bitumen is less susceptible than penetration bitumen and viscosity bitumen types.

Softening Point Test Methods of Bitumen in International Standards

Various standard methods are provided to determine the bitumen softening point, as follows:

- ASTM D36 (the most common)

- ASTM E28-67/E28-99

- ASTM D6493 – 11

- IS 1205

- EN 1427

- IP 58

- ISO 4625

- JIS K 6863

The ring and ball test by the ASTM D36 method will be described hereunder.

Softening Point Test of Bitumen by ASTM D36:

The component of the ring and ball apparatus and test steps are given below:

The apparatus consists of:

- Two steel balls

- Two brass rings

- A glass beaker

- Thermometer

- Ring holding bases (Support)

- A heater

The Procedure of Bitumen Softening Point Test

-Sample preparation:

- Heat the bitumen sample to a temperature of 75-100 ° C until the bitumen is completely liquid.

- Prepare a mixture of glycerin and dextrin in equal proportions. Then coat the surface of the metal or glass plate. This prevents the bitumen from sticking to the plate

- Heat the rings to approximately the same temperature as the molten bitumen. Place them on the plate coated with the mixture of glycerin and dextrin.

- Gently pour the heated bitumen a little over the volume of the rings inside each ring. Let them cool at room temperature.

- When the test pieces have cooled, the extra bitumen can be removed with a slightly heated knife

-Procedure

Fill the water bath with boiled distilled water at a maintained temperature of 5 °C.

Fix the rings filled with bitumen in the support frame and place them in the water bath at 5 °C for 15 minutes. Cool the steel balls to a temperature of 5 °C.

Place a steel ball on the top of the rings attached to the support. Place this assembly in a beaker filled with distilled water. The water level must be at least 50 mm higher than the ball’s top surface.

Put the beaker on the heater and adjust the stirrer and thermometer. Allow the beaker to be heated at a uniform rate of 5 ± 0.5 °C/min.

Continue heating until the bitumen becomes soft and the ball starts to move down because of its weight.

Note the temperature from the thermometer when each ball touches the plate bottom.

The average value of the softening point of two balls (to the nearest 0.5 °C) is the softening point of Bitumen.

Note: For bitumens with softening points between 40 – 60 °C, the maximum difference between the two readings should not be more than 1 °C. For the softening point between 61 – 80 °C the difference should be less than 1.5 °C. Else the test is invalid and it is repeated.

Click to learn about 11 Major Bitumen Tests.

Softening Point Test of Bitumen Conclusion

As bitumen does not have a specific melting point, its softening point is measured. By ring and ball apparatus, we measure the softening point. It helps us to know what type and grades of bitumen can be used in different weather conditions.