Bitumen emulsion consists of fine bitumen droplets that are dispersed and suspended in the aqueous phase. These small droplets may join together and form clots. In this condition, it is said that the emulsion loses its stability and as a result, its properties change.

Maintaining bitumen emulsion stability and therefore its properties can be subjected to changes caused by storage and transportation conditions.

This article introduces bitumen emulsion storage tanks and the best handling, storing, and sampling conditions for this product.

The Properties of Bitumen Emulsion Storage Tank

Storage tanks for bitumen emulsion should have the below specifications:

1- Storage tanks must be insulated

The storage tanks for bitumen emulsion must protect this product against freezing and heating. Because freezing leads the bitumen emulsion to become two phases.

If bitumen and water are separated from each other, they will no longer have the performance of bitumen emulsion. Also, it will be difficult to remove the deposited bitumen from the container.

Find out what bitumen emulsions are used for here.

2- Storage tanks must be vertical

A layer of bitumen forms on the surface of the bitumen emulsion which is exposed to the air. As a result, the amount of bitumen in the bitumen emulsion decreases, which causes changes in the properties of the bitumen emulsion.

This can be prevented by using vertical and long storage tanks so that there is minimal contact between the bitumen emulsion surface and the air.

3- The bitumen emulsion should be mixed gently every two weeks

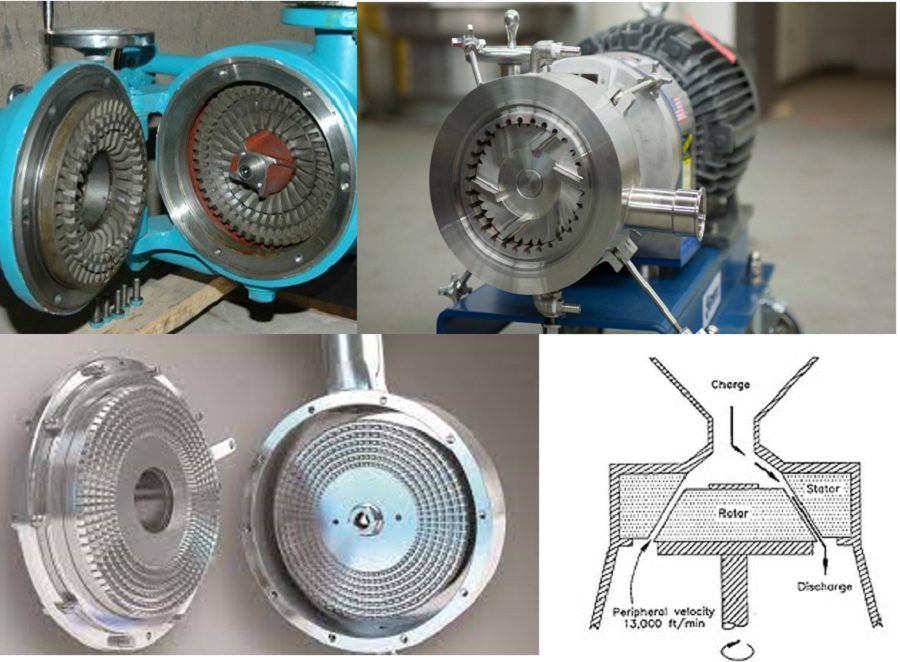

In order to prevent the separation of bitumen and water, it is necessary to stir the bitumen emulsion almost every two weeks.

Propellers should be used for stirring. They must be placed one meter away from the bottom of the storage tank. These propellers have a large diameter and low speed.

High speed leads to changing the viscosity of the product.

You can also use the pump to move the contents of the container from top to bottom.

9 Tips on Handling, Storing, and Sampling of Bitumen Emulsion

1- Bitumen emulsion should be kept in temperature ranges between 10°C and 85°C. This range prevents separating bitumen and water or changing bitumen emulsion properties due to freezing and water evaporation.

2- The bitumen emulsion must not be applied on surfaces with temperatures higher than 100°C. Because the water evaporates and due to that, bitumen emulsion properties are changed and it settles down rapidly.

3- Compressed air should not be used to stir bitumen emulsion because it will lead to breaking the emulsion.

4- Avoid over-pumping the bitumen emulsion.

Bitumen emulsion should not be pumped at high speed and for short periods of time. This leads to a decrease in the viscosity of emulsion bitumen.

Also if the pump is close to the surface, it is possible for air to enter the bitumen emulsion. As a result, water and bitumen are separated.

Read about the viscosity test of bitumen emulsion here.

5- To transfer bitumen emulsion, it should be noted that the pump and transfer valve are clean, or do not contain materials incompatible with bitumen emulsion.

For example, To pass the cationic bitumen emulsion, the pump and valve must be washed if the anionic bitumen emulsion passed through them.

6- To dilute the bitumen emulsion, water should be added to the emulsion. The water must be mixed very slowly into the emulsion.

Only medium and slow setting types of bitumen emulsion are suitable for this purpose.

Check different types and grades of bitumen emulsion here.

7- Since emulsion bitumen and air contact surfaces form a bitumen layer, it is best to pump bitumen emulsion from the bottom of the tank.

8– Due to the possibility of bitumen layer formation, the contact surface of bitumen emulsion or the air above it should not be exposed to heat or strong oxidizing agents and there must be enough ventilation.

9- Bitumen sampling must show the actual properties of the whole bitumen emulsion.

Sampling methods should be done according to ASTM D-140 and AASHTO T-40 standards.

Factory or storage tankers are the best sources for sampling.

If the two above options are not available, the sample should be taken before transportation.