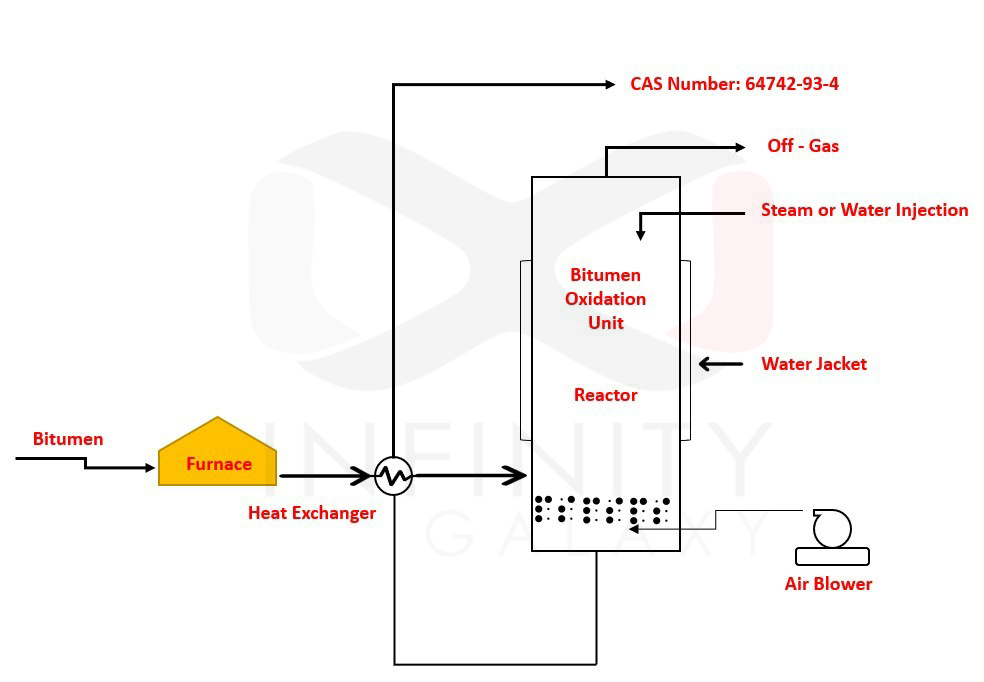

Oxidized bitumen production is done in 5 steps:

- Heating the Bitumen

- Transferring bitumen to oxidation unit

- Blowing air to bitumen

- Cooling bitumen with water or steam injection

- Packing

More details of the oxidized bitumen production process is described below.

Bitumen Oxidation Unit Equipment

The bitumen oxidation unit consists of:

- A reactor

- Air blower

- Off-gas treatment facility

- Temperature control equipment

Oxidized Bitumen Manufacturing Explanation

Raw Material

The raw material of oxidized bitumen is bitumen penetration grade or viscosity grade bitumen.

In this process, the air should pass through the bitumen to obtain the oxidized bitumen.

Heating and Transferring the Bitumen

In the first step, bitumen is passed from the furnace to be heated. Then it should be transferred into the reactor of the oxidation unit.

As the bitumen volume increases due to the air blowing and it may overflow, the oxidation unit is filled up to 70%.

Blowing Air to Bitumen

The air should be blown from the air blower to the rector. The flow rate of the air should be in the range of 85-140 m3/min. It means that in 1 minute, the air with the volume of 85 to 140 m3 should pass through the raw material.

The air blowing is done in the temperature range 215-260 °C.

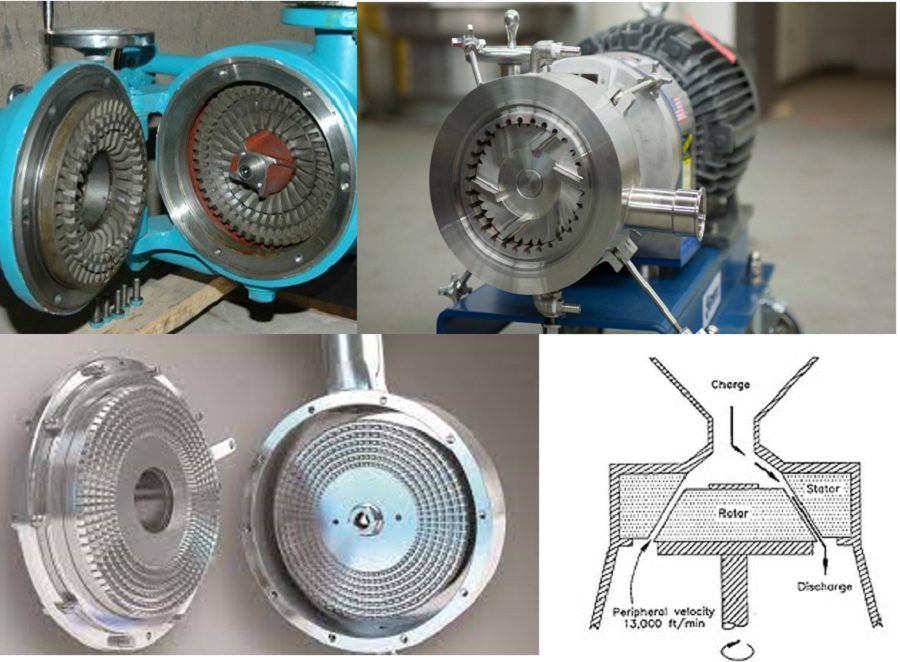

In the reactor there are baffles or agitation systems. This system is used to ensure that the bitumen is mixed well with air.

In this process, the main purpose of the bitumen oxidation is to stiffen the bitumen. In the air blowing process, when the bitumen becomes stiff, its three parameters change.

Its softening point increases, its penetration value decreases and its viscosity increases.

The above parameters that should be changed to obtain the oxidized bitumen are the physical properties of the bitumen. To change them, the temperature of the reactor should be very high.

So due to the high temperature, the bitumen oxidation process produces heat.

For this reason, in order to control the bitumen temperature, the reactor should be covered with a water jacket.

Instead of a water jacket, a water spray facility can be placed on the head of the reactor.

During the process, harmful gas which is called off- gas is produced in the reactor. This gas contains oxygen that can explode if it is not controlled.

Water or Steam Injection

To reduce the oxygen content of this off-gas and cool the bitumen, the steam or water should be injected into the headspace of the reactor.

In this process, in addition to physical properties, some chemical properties also change. Molecular weight and polarity are two chemical properties that increase in the oxidation process.

The oxidation process can be done without adding a catalyst. But in many refineries, engineers prefer to add the catalyst to increase the speed of the reaction in the oxidation unit.

The bitumen properties including viscosity, penetration degree, softening point and reactivity can affect the rate of oxidation reaction. The harder the bitumen, the less time and less air is needed to oxidize the bitumen and the rate of reaction is higher than the softer bitumen.

For example if the raw material to produce oxidized bitumen 90/15 is the bitumen penetration 60/70, less time and less air is required compared to bitumen 80/100. Also, the reaction rate is higher. Because bitumen penetration 60/70 is harder than bitumen penetration 80/100. Its penetration degree is less than bitumen penetration 80/100 and its softening point is higher than it.

Also, some operational parameters like temperature, pressure, air flow rate, degree of agitation, the ratio of air to feedstock and type of catalyst can affect the rate of oxidation reaction.

Air blowing to the bitumen finishes after sampling from the reactor and testing the obtained bitumen properties by bitumen tests. If the parameters like softening point and penetration degree are in the range that is defined by engineers, the oxidized bitumen manufacturing will stop.

Packing

The final product is the hard bitumen that can be packed in different types of 25 KG cartons or new steel drums.

Infinity Galaxy, Oxidized Bitumen Supplier

Infinity Galaxy is an oxidized bitumen supplier based in the Middle East that has exported high-quality products to different Asian and African ports.

If you have any questions or inquiries related to oxidized bitumen, you can keep in touch with us on WhatsApp or leave a comment.