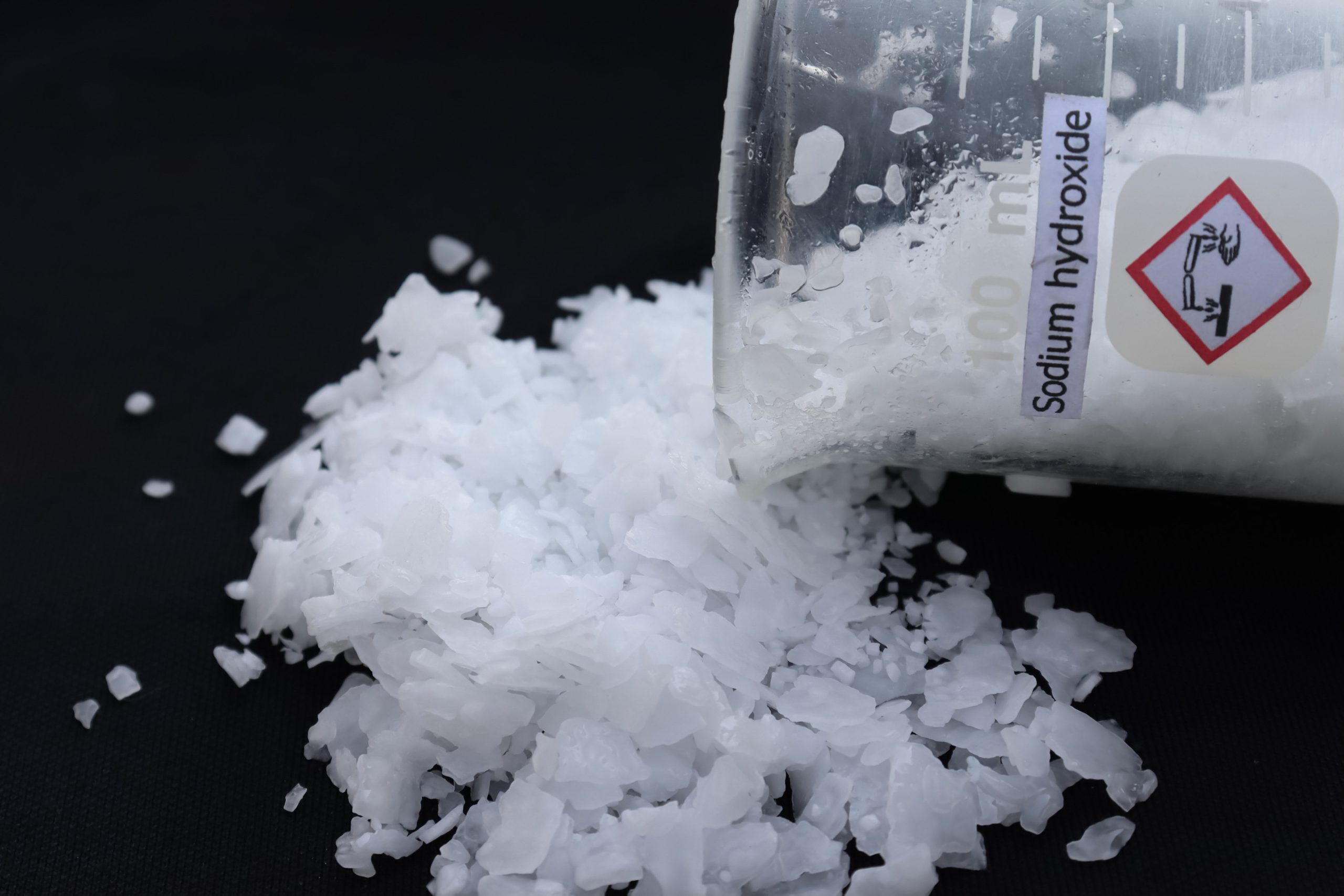

Caustic Soda or sodium hydroxide is one of the most widely used products in the pulp and paper industry. In this article, we will look briefly at Caustic Soda applications in this industry.

Traditionally, Caustic Soda has been used in almost every stage of paper production. Besides, in recent years, due to environmental concerns about wood resources, paper recycling has grown to be a considerable industry, and the use of Caustic Soda in paper recycling has gained increased attention.

Thus, Caustic Soda applications in the pulp and paper industry can be broadly classified into two categories: paper production and paper recycling.

Caustic Soda in Paper Production

Paper production is generally divided into three milestones, and in the first two of these three stages, Caustic Soda is directly used:

- Pulping (Cooking)

Paper is made from cellulose, and although today, due to the scarcity of wood resources, other raw materials such as agricultural waste, vegetable residues, waste paper and even old clothes are used, wood is still the main source of cellulose.

However, wood does not contain only cellulose fibers. There are additional non-cellulosic substances in wood that must be removed and the most important of which is lignin, a substance found in the texture of wood that acts as a glue, binding the wood’s cellulose fibers together.

To facilitate the removal of lignin and other non-cellulosic materials, the input wood must be cooked until it becomes pulp. This process, referred to as pulping, utilizes Caustic Soda at high temperatures and pressures to dissolve lignin.

- Pulp Bleaching

The pulp is yellow due to the presence of lignin, which is not desirable for the final product. The pulp bleaching stage is divided into two substages: bleaching and extraction.

The bleaching stage employs a bleaching chemical (such as Hypochlorite), and an alkaline environment (one with a high pH) is ideal for maximum efficiency. Almost all manufacturers use Caustic Soda at this stage to control the pH.

During the extraction stage, the pulp is oxidized to allow the lignin to be solved in an alkaline solution and extracted from it. Also, at this stage, Caustic Soda is used to solve and extract the lignin content. Caustic Soda has no cost-effective alternatives at this stage for a variety of reasons, including lower cost and improved performance.

- Papermaking

Finally, the paper pulp is combined with plenty of water and fed through a paper machine. The paper machine is a giant machine that transforms the paper pulp into the desired final product (which is paper with varying dimensions, transparencies, and strengths) through the steps of forming, pressing, and drying.

Caustic Soda in Paper Recycling

Paper recycling begins with classifying and grading waste papers according to their recyclable cellulose content. The next step, called de-inking, involves smoothing and swelling the input waste paper with Caustic Soda, which separates the ink from the papers.

The final stage of paper recycling is similar to the final stage of paper production, when the paper pulp is fed into the paper machine, and the final product is produced.

As discussed in this article, caustic soda is a critical processing material used in almost every stage of the pulp and paper industry.

Click on Related pages:

What is Caustic Soda?

Caustic Soda Applications in Food Industry

Caustic Soda Price