Bitumen Flexitank Definition

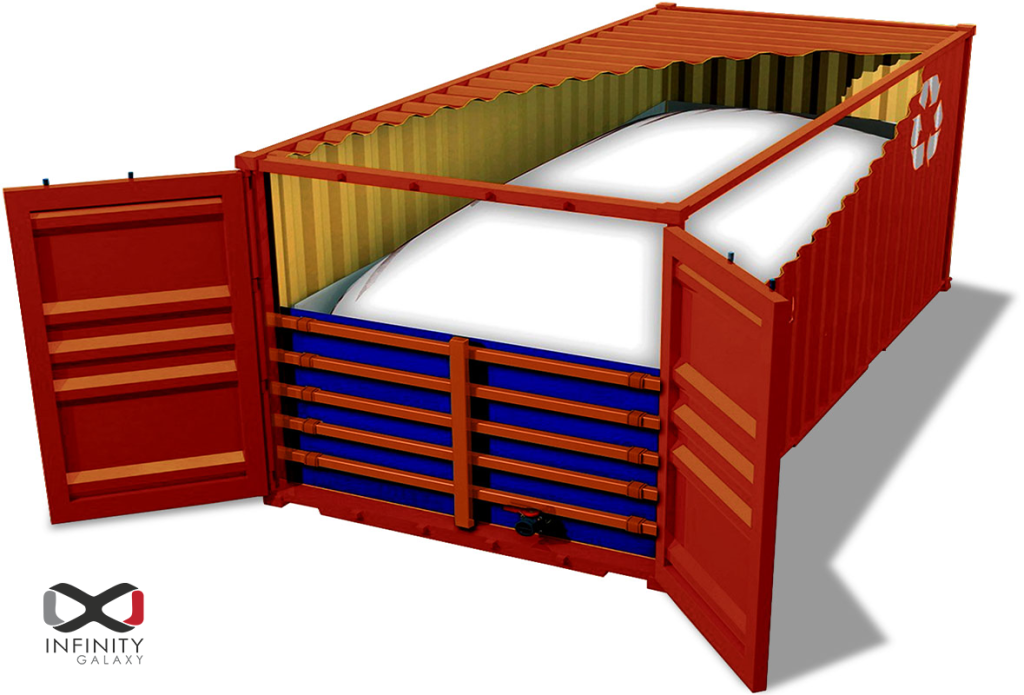

Flexitank is a type of bitumen and liquid petrochemical packing. It is suitable for non-corrosive and non-hazardous liquid products.

Being cost-effective and eco-friendly have made this packing popular in different industries. Contrary to steel drums and IBC, it contains more bitumen.

Flexitank is a kind of single and multi-layer thick bag. Based on the number of valves, it can be categorized into different types including single valve and two valves.

Bitumen Flexitank Weight

Flexitanks have a capacity of 14000 to 24000 liters that can be placed in a 20 ft. container.

However, to carry bitumen by a flexitank, each flexi can hold 20 tons of bitumen per 20-foot container.

The important tip is that flexitank cannot be used in 40-foot containers because flexi must be protected on all four sides with the body of the container.

Bitumen Flexitank Material

The standard flexitanks are made of polyethylene and polypropylene. The Flexitank is able to tolerate hot liquids, which are filled with more than 120 degrees into it.

This packing is durable. It shows good resistance to the pressure that the liquid puts on the internal layer of the flexitank.

This flexitank material ensures that the body is not damaged when the molten bitumen is loaded, the flexi is easily filled with bitumen, and there is no problem for flexi when removing the bitumen.

Bitumen Flexitank Specification

The bitumen flexitank dimension is as below:

Flexitank | Length | Width | Height | Material | Capacity |

| 590 cm | 234 cm | 170 cm | Polyethylene Polypropylene | 14000 – 24000 |

How To Use Bitumen Flexitank

After insulating the container walls, it enters the refinery area. Insulating the walls ensures that no damage is done to the flexitank body after filling the bitumen. Molten bitumen with a maximum temperature of 110 degrees enters the flexitank through the pipe.

After filling the flexitank with a maximum net weight of 20 tons, it should be left in an open door container for a few hours, so that the bitumen changes from molten to solid.

The temperature of the bitumen is equal to the ambient temperature. The container should also be closed.

After the inspection and custom container door sealing, the containers are transferred to the deck of the ship.

At the destination, the containers must be placed on a low slope and the bitumen removed after leaving the ship.

How to Load Bitumen in Flexitank

Here are two videos showing how to load the bitumen flexitank.

Flexi Tank is used as a suitable packing for all kinds of petrochemical products, including bitumen, base oil, and recycled base oil.

Flexi installation is very important that if not installed properly, it will cause leakage and cause many problems during operation and even at the destination.

Bitumen Flexitank in Comparison to other Bitumen Packaging

Carrying bitumen in a flexitank has the following advantages over another bitumen packing:

- Flexitank is an eco friendly packing.

- In flexitank packing, instead of 110 drums per container or 20 jumbo bags per container, only one flexitank is used, which is easier to unload in terms of operation.

- The price of Flexitank packing is lower than other types of bitumen packing

Important Points in Using Flexitank for Carrying Bitumen

Due to the fact that 20 tons of bitumen is stored in each flexitank, care must be taken when filling, transporting the ship, and leaving it. Any unloading without planning must be avoided. Otherwise, it will cause irreparable damage.

A flexitank is loaded with solid bitumen at room temperature and at room pressure. At the time of off-loading, the bitumen should also be at room temperature. The ramp and temperature should be changed gradually as the bitumen is offloaded.