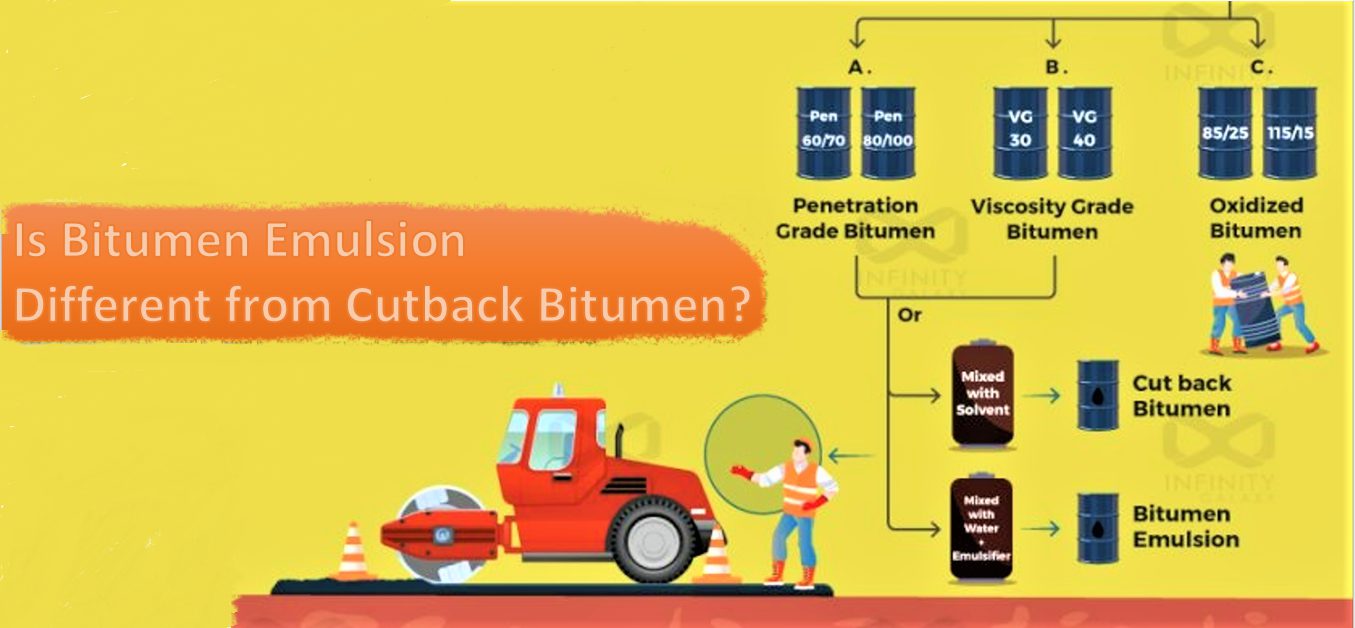

In the complex world of bitumen, some grades are suitable for hot techniques of road construction and some others suit cold techniques. For cold techniques of road construction, the viscosity of bitumen is reduced, thus, there is no need for heating it before application. Low viscosity bitumen is highly recommended whenever the weather is cold or a bituminous spray is needed.

Bitumen emulsion and cutback bitumen are two well-known types of bitumen suitable for cold techniques; however, their application and advantages are different. In what follows, we shed some lights on bitumen emulsion’s application and answer the question of why it is better to use emulsified instead of cutback bitumen.

What is Bitumen Emulsion Used for?

Bitumen emulsions were introduced to the industry in the 20th century, mainly for spray applications; but today, they are used for both mixing and spraying in road construction and pavement maintenance. In what follows we will explain more about bitumen emulsion uses including preventive and corrective maintenance.

Bitumen emulsions are the best choice for tack coats, which are applied between various layers of asphalt pavement. Emulsified or cutback bitumen play the role of tack coats in road construction to significantly increase the strength and fatigue life of pavements at a low cost.

To renovate and waterproof old roads, we can use emulsion or cutback bitumen. Known also as surface dressing, chip seals are one of the most cost-effective methods of pavement preservation, since they protect underlying pavement from oxidation and aging.

In order to give a uniform texture to roads, engineers use slurry seals. This mixture of bitumen emulsion, aggregates and mineral fillers is sprayed on the pavement to seal it and make the surface weather-resistant.

Micro surface is another form of slurry in road construction, which is composed of polymer modified bitumen emulsion. The existence of dense-graded aggregates in this mixture makes it stronger and more durable than a slurry seal. Moreover, the quick setting micro surface emulsion allows traffic to begin using the new surface in about an hour.

Different Types of Bitumen Emulsion and Their Application

To make a road surface more durable, various properties of bitumen emulsion should be considered. At Infinity Galaxy, we test bitumen emulsions to classify them based on viscosity value, the electronic charge of their particles, and the setting type. You can read our comprehensive guide on different tests of bitumen emulsion.

If you are interested, you can read our comprehensive guide on different tests of bitumen emulsion.

In what follows, we explain the applications of bitumen emulsion based on the result of major tests:

Application According to Viscosity Level

For deciding about the best grade of bitumen emulsion that suits your required application, referring to the results of viscosity tests is necessary.

For dense graded aggregates, a thinner viscosity of bitumen emulsion is needed; however, to achieve an appropriate thickness, open graded aggregates require a thicker viscosity of bitumen emulsion.

Application According to Setting Type

Choosing the right setting type is crucial when bitumen emulsion is applied on a surface.

Rapid setting emulsion sets quickly in contact with aggregates, therefore, it is highly used in low surface of roads, particularly chipseals and surface dressing.

Medium setting emulsion are used in premixing of bitumen emulsion and coarse aggregate, particularly open graded mixes.

Slow setting emulsion sets very slowly. That’s why it is suitable for being mixed with aggregates of high surface area. They are the most stable type of emulsion and can be used in dense graded aggregate bases, slurry seals, and recycling asphalt.

Application According to the Electronic Charge of Emulsion Particles

Bitumen emulsions are always examined in terms of the electronic charge of their particles.

A particle test charge leads to the classification of bitumen emulsion into two categories of Anionic and Cationic (Click for more details). Some aggregates mix better with anionic bitumen emulsion and some others are a better solution to cationic bitumen emulsion.

Bitumen Emulsion

Advantages and Disadvantages

What is the Difference between Ordinary Bitumen and Emulsion Bitumen?

Bitumen emulsion is a chemical combination of bitumen, water, and an emulsifying agent. This liquefied bitumen is more efficient than ordinary bitumen for road construction, particularly in a lower temperature. With a lower viscosity in comparison to ordinary bitumen, this type of binder doesn’t need to be heated before being applied to the surface. After the application of bitumen emulsion, the water releases and the bitumen mix starts to set.

As a low temperature technique, using emulsified bitumen is also suitable for reducing emissions and energy consumption. The construction of a roadway with bitumen emulsion (cold-mix bitumen) is likely to consume approximately half the energy of paving a road with hot-mix bitumen.

What are the Advantages of Bitumen Emulsion to Cutback?

Both emulsion and cutback bitumen have a lower viscosity level in comparison to ordinary bitumen; however, they are not the same. In order to loose viscosity, bitumen is mixed with petroleum solvents such as kerosene, naphtha, diesel oil, etc. to form cutback bitumen. In emulsions the solvent is water, which reduces the risks of fire and makes the final binder Eco-friendlier than petroleum-based cutbacks.

Bitumen emulsions is more tolerant than cutback bitumen and develop final strength more quickly. This type of bitumen give good results even when chippings of the surface are damp.

Bitumen emulsion is also compatible with other water-based binders like rubber, latex, and cement, since it does not include any petroleum solvents. Being water-based makes this type of bitumen more suitable for application in a rainy weather as well.

What are the Disadvantages of Bitumen Emulsion?

The main challenge of using bitumen emulsion is happen to be transportation. Although these types of bitumen do not need heating during the transportation, they are likely to lose their viscosity after a period of time, mainly because they contain a reasonable amount of water,

To ensure the stability of bitumen emulsions during storage or transportation, some producers add calcium chloride to bitumen. Calcium chloride is applied to reduce the osmosis of water into the bitumen and the increase in viscosity during the storage.

For choosing the best grade and type of bitumen emulsion, you need to be an expert. Depending on the aggregate type, the setting time, temperature of the site, etc. bitumen emulsion can behave differently during the time. In case you need any information about bitumen emulsion and its application, you can add a comment below or send an email here. Our support team at Infinity Galaxy are ready to help you pick the right grade of bitumen emulsion.