What is Ductility Test of Bitumen ?

Ductility is one of the important properties of bitumen that shows the capability of tolerating deflections that occur on the road. Consequently, the probability of cracking becomes lower, and the life span of asphalt is increased. Ductility is measured by the ductility test.

In this test, the cohesive strength of bitumen is obtained by applying stresses to it.

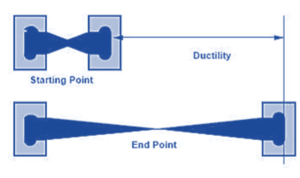

In this experiment, bitumen is poured into the tester and pulled with a speed of 5 cm/min at a temperature below its softening point. The length of bitumen stretched in centimeters before tearing apart is the bitumen ductility.

ِDuctility is usually within the range of 5 cm to over 100 cm. The acceptable value of bitumen ductility should be more than 50 cm. However, this value should be 100 cm or more for road construction.

A ductility test can measure the cohesive strength of bituminous products like oxidized and cutback bitumen.

Here is an example of the ductility value of viscosity bitumen grades based on IS 1208 method:

| Paving Grades | Minimum Value of Ductility @ 25 °C |

| VG 10 | 75 cm |

| VG 20 | 50 cm |

| VG 30 | 40 cm |

| VG 40 | 25 cm |

We prepared the video below to help you understand the steps of ductility testing.

Why do We Use the Bitumen Ductility Test?

During the day, the temperature and road traffic are higher. Therefore, if the bitumen is not ductile enough, cracking will occur. Temperature changes cause bitumen to expand and contract.

Therefore, bitumen must have sufficient ductility to be resistant to temperature changes. Furthermore, it must not tear in heavy traffic and must adhere well to the aggregates.

The ductility of bitumen is inversely related to bitumen hardness which is measured by penetration test. Bitumen with low ductility properties will be hard and brittle. Hard bitumen is not suitable for cold climates.

Also, in hot weather very soft bitumen can cause the surface of the asphalt to ripple. As a result, it is important to use a ductility test to measure this property before construction.

Check Out the “Types of Bitumen Used in Road Construction“

Ductility Test Methods of Bitumen in International Standards

Bitumen ductility test can be performed by following standard methods:

- ASTM D133

- ASTM D 6084

- AASHTO T51

- IS 1208

- EN 13589

- EN 13703

- IP 520

- JIS K 2207

The ductility test based on the ASTM D113 method will be described as follows:

Equipment for Fuctility Test of Bitumen

The following equipment will be required:

1. Briquette

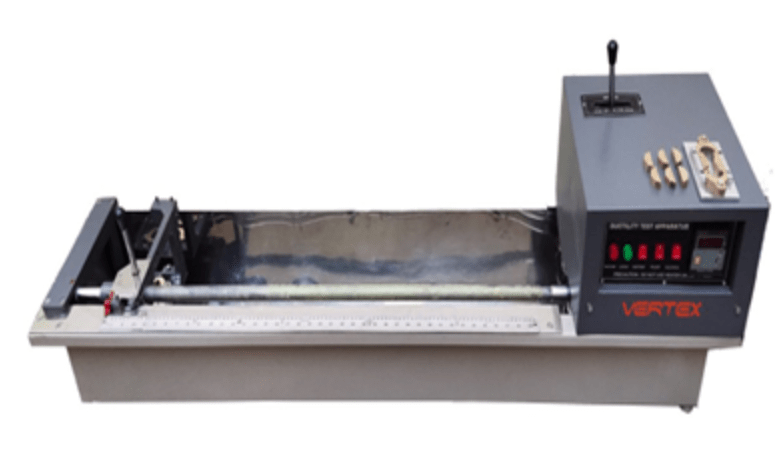

2. Pulling device with distance measuring dial

3. Water bath

4. Thermometer

5. Brass plate

6. Knife

The Procedure of the Ductility Test of Bitumen

Bitumen samples should be heated between 75 °C and 100 °C above their softening point. When bitumen becomes completely liquid, pour it into the set of briquette mould which is placed on a brass plate. The brass plate should be coated with a mixture of glycerin and dextrin to prevent bitumen from sticking.

After all, the equipment is cooled at room temperature, put the whole set in a water bath that is kept at 27 °C. Then remove them from the water bath and flatten the surface of the sample with a hot knife. Take apart the mould from the plate.

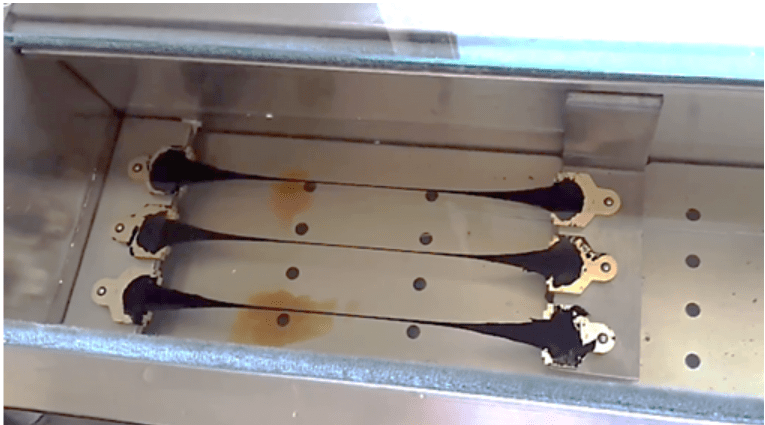

Place the mould assembly in the water bath and attach the mould clips to the machine. This step must be done carefully without applying any additional force to mould bitumen.

After calibrating the pointer to zero, start the machine. The clips are pulled horizontally at a constant speed of 50 millimeters per minute. The ductility value is the distance at which the bitumen thread stretches and then ruptures.

The three recorded values of mould samples are averaged to report the ductility of the bitumen specimen. The three recorded values must be within ± 5 percent of their mean value in a test.

Note: If the bitumen sample reaches the water bath bottom or the water surface, the test is not normal. The density of water must be risen with additives to have a normal test. If the normal test does not achieve, the ductility is not obtainable.

Click for other Bitumen Test

ِDuctility Test of Bitumen Conclusion

Ductility test is done on pure and liquid bitumen, it measures the cohesive strength of bitumen sample. Generally it is in the range 5 to 100 cm.