MC30

MC-30 is a type of medium curing cutback bitumen which is suitable for cold regions. It applies in road maintaining operations, including tack coats and slurry seals.

This type of liquid bitumen comprises a penetration grade bitumen and a petroleum based solvent.

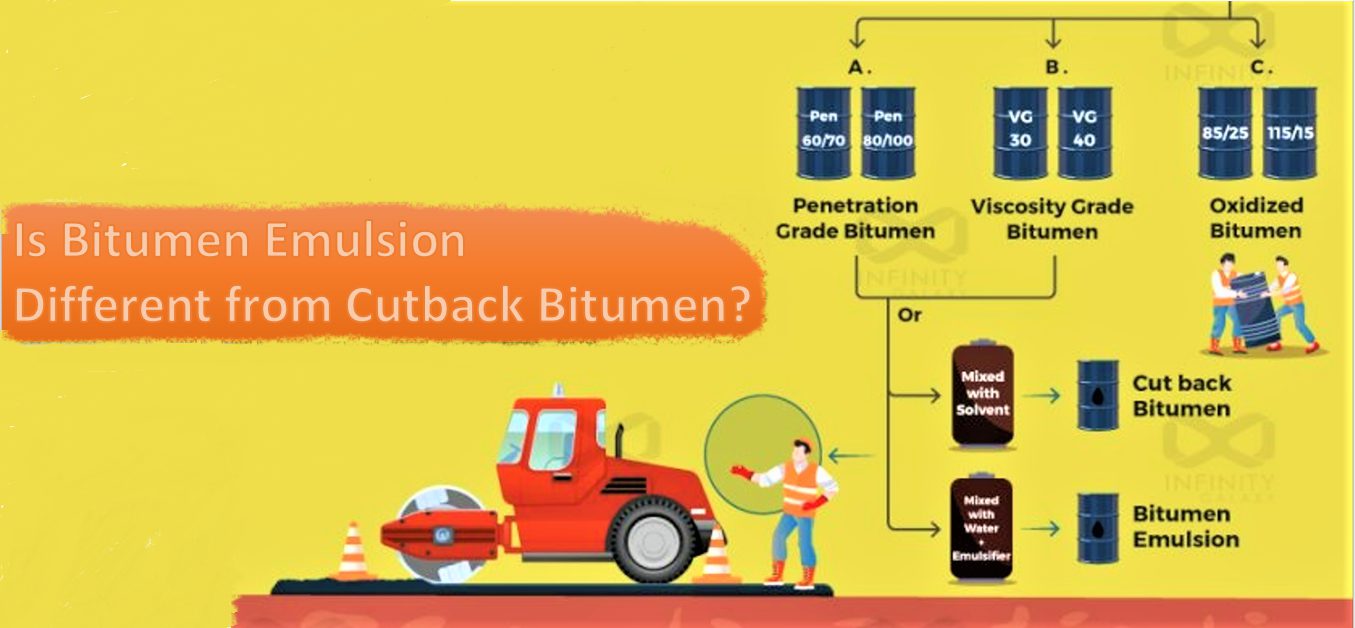

Liquid bitumen is classified into four different types: Cut Back and bitumen emulsion.

According to the kinematic viscosity test, medium curing cutback grades include MC-30, MC-70, MC-250, MC-800 and MC-3000, which MC-30 is the thinnest at 60 ◦C.

In the following you can read more about MC30.

What is MC-30 Cutback Bitumen?

MC 30 cutback bitumen has the minimum viscosity among all of the medium curing cutback bitumen, which contains approximately 42% of Kerosene and 58% penetration grade 80/100.

In cutback bitumen, the solvents help the bitumen to have a lower viscosity at ambient temperature.

To understand what MC 30 bitumen means, we need to consider that cutback bitumen has three types, rapid curing or RC, medium curing or MC, and slow curing or SC.

We put MC 30 bitumen under the category of medium curing cutback bitumen because its average curing time on a surface is 48 hours.

MC30 bitumen is produced by adding intermediate volatility solvents (generally kerosene) to pure bitumen. The production of bitumen MC 30 requires high skills and expertise, which can only be found in refineries. This means, bitumen MC-30 cannot be simply produced by adding solvents to bitumen. There are quality standards and safety rules that need to be followed.

For more details on purchasing, check the latest MC 30 cutback bitumen price.

The Application of MC30

MC-30 bitumen is widely used as a primer in coating roads. The mc-30 prime coat application rate is based on the engineer’s decision according to the road surface condition. Generally, 0.7 L/M^2 for MC30 is suitable, the bitumen residue after evaporating the MC30 solvent will remain 0.35 L/M^2. This grade of bitumen is sprayed over a granular base to prepare it for laying an asphalt mixture. With its low viscosity, MC- 30 cutbacks will coat and bond loose aggregates on the surface of the base.

In the article of different types of bitumen used for road construction, you can read about the application of MC30 in protective asphalts, prime coat and surface coating.

MC-30 will also waterproof the finished base material and enable it to bond to a subsequent pavement layer.

With its low viscosity, bitumen MC-30 is recommended for being used when the base is dense and hard to penetrate. When the surface is open, we use high viscosity MC grades for prime coating.

In comparison to MC-250, cutback MC-30 needs no heating in hot seasons.

The main usage of mc-30 is in prime coating, cold mix asphalts and bitumen paints.

MC-30 bitumen is fully capable of bonding the base to the first layer of hot mix asphalt. This grade of MC cutback bitumen is a unique primer which provides temporary seal to prevent the surface water from penetrating through the surface.

MC-30 is suitable for being mixed with other aggregates in cold mix techniques. Cold mix asphalts are generally used in very low traffic roads in a cold climate.

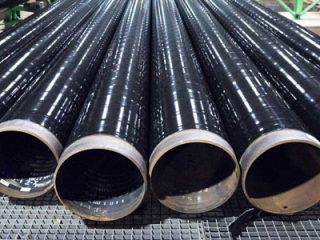

MC-30 bitumen is suitable for coating and protecting steel pipes from chemicals and UV light. It also protects surfaces from rust.

The Advantages of MC-30

Unlike rapid curing cutback bitumen (RC), MC-30 has Kerosene as its solvent, which is safer than gasoline or naphtha in RC cutbacks.

In comparison to bitumen emulsions, MC-30 cutback is a better primer than bitumen emulsions. Compared to many other grades of bitumen emulsion, it penetrates the compacted base more effectively.

How to Use MC-30 Cutback Bitumen?

Before using MC-30 cutback as a primer, the surface of the road should be clean and dust-free by sweeping. The surface that is coated with MC-30 cutback must be allowed to dry, before the construction of other layers.

The average drying time for MC-30 bitumen is 48 hours. This period of time might extend based on the porosity of the base or the weather conditions.

The viscosity of cutback bitumen MC-30 is low enough to let spraying at ambient temperature. However, to make sure that the bitumen will penetrate the surface well, you need to heat the binder prior to spraying.

In the time of heating, it is required to pay attention to the MC-30 bitumen flash point and avoid fire. In the picture below, you can see the road construction steps that MC30 plays the role of binder.

The Difference Between MC30 and MC70

As mentioned above, the main difference between MC-30 and MC-70 bitumen is their kinematic viscosity. For MC-30 the kinematic viscosity is 30 to 60 centistoke, but for MC-70 bitumen it is 70 to 140 centistoke.

Due to the difference in their kinematic viscosity and other items of specifications, the application of MC-30 cutback bitumen is also different from MC-70. We use MC-30 in cold weather, but MC-70 is preferred in hot and dry regions.

The Difference Between MC30 and MC3000

The composition of MC 30 is generally a mixture of 58% penetration grade 80/100 and 42% kerosene. While, MC3000 is composed of 85% penetration grade 80/100 and 15% kerosene. MC 30 has the lowest viscosity among all grades of medium curing, and MC 3000 has the highest viscosity.

MC 30 Bitumen Price

MC-30 bitumen price is higher than ordinary bitumen. In the production of bitumen MC 30, we add solvents such as kerosene to bitumen, which is more expensive. Therefore, the MC-30 price is a bit higher than other grades of bitumen. If you require to consult before buying MC-30, contact us to get the exact price of this type of bitumen.

Packing of Cut-Back Bitumen MC-30

Packing of MC30 bitumen is barrel. A MC barrel weighs about 220 kg, and only 80 barrels can fit in a 20 ton container.

Specification of MC 30

According to ASTM D2027 M-13, the specification of MC-30 is as shown in the table below.

| Cutback Bitumen Medium-Curing-30 Specifications | ||||

|---|---|---|---|---|

| Properties | Specification Limit | Test Method | ||

| Min | Max | |||

| Kinematic viscosity at 60°c ,cST | 30 | 60 | ASTM D2170 | |

| Flash point(tag open cup), °C | 38 | – | ASTM D3143 | |

| Distillation test Distillate, volume per cent of total Distillate to 680°F (360°C) | ||||

| Residue from distillation to 437°F (225°C) | – | 25 | ASTM D402 | |

| to 500°F (260°C) | 30 | 75 | ||

| to 600°F (316°C) | 75 | 95 | ||

| to 680°F (360°C), per cent volume by difference | 50 | – | ||

| Test on residue from distillation test | ||||

| Viscosity at 140°F (60°C) | 30 | 120 | ASTM D2170 | |

| Penetration 77°F (25°C) 100g, 5s mm | 120 | 300 | ASTM D5 | |

| Ductility 77°F (25°C) 5cm/min cm | 100 | – | ASTM D113 | |

| Solubility in trichloroethylene % | 99 | – | ASTM D2042 | |

| Water, percent volume | – | 0.2 | ASTM D95 | |

Does this type of bitumen need to be heated before use?

However that MC30 has a low viscosity and it doesn’t need to be heated in ambient temperature, but it’s better to heat it before spraying to penetrate well into the surface.

Can we replace MC30 by bitumen emulsion?

Yes. MC-30 bitumen can be replaced by slow setting bitumen emulsions in some applications such as prime coats; however, using MC-30 is much preferred to emulsions, since it penetrates deeper into the compacted bases and delivers better results.

What are the other petroleum distillates that are used for preparation of cutback bitumen?

These distillates are naphtha, diesel oil and furnace oil.

Infinity Galaxy, MC-30 Cutback Bitumen Supplier

The international bitumen supplier, Infinity Galaxy, is sending hundreds of tons of MC30 cutback bitumen in barrels to more than 12 countries across the world.

Since that this bitumen may become a two-phase combination, we are careful and constantly track the condition of bitumen by our international inspectors.

We assure you that you will receive the bitumen with the same quality. We strive to offer the highest quality of different types of bitumen, including MC-30 and other petrochemical products, based on international standards.

We will deliver you the qualified bitumen on time, in the best type of packaging. If you’re looking for an appropriate bitumen to meet your need, You can also fill the form below to register your order.

"*" indicates required fields