What is Cutback Bitumen?

The industry is sometimes in need of low viscosity bitumen. There manufacturers came to a solution to deliver cutback bitumen which is a low viscosity liquid dissolved in a solvent. The main advantage of this type of bitumen is that there is no need to heat it before using.

Cutback bitumen is made by the addition of controlled amounts of petroleum extracts such as kerosene, naphtha, diesel oil, and furnace oil to perform as a solvent.

Although these adhesive materials are added to lessen the need for heating before using, they will evaporate as the bitumen is applied. This process is done for a temporary reduction of the bitumen viscosity.

Cutback bitumen is more appropriate for cold regions than the others. Primer sealing and sprayed sealing are some items for which cutback bitumen is suitable.

In the Types of Bitumen Used for Road Construction, you can read more about different grades of cut back bitumen that are used in these asphalts to maintain the road from damages.

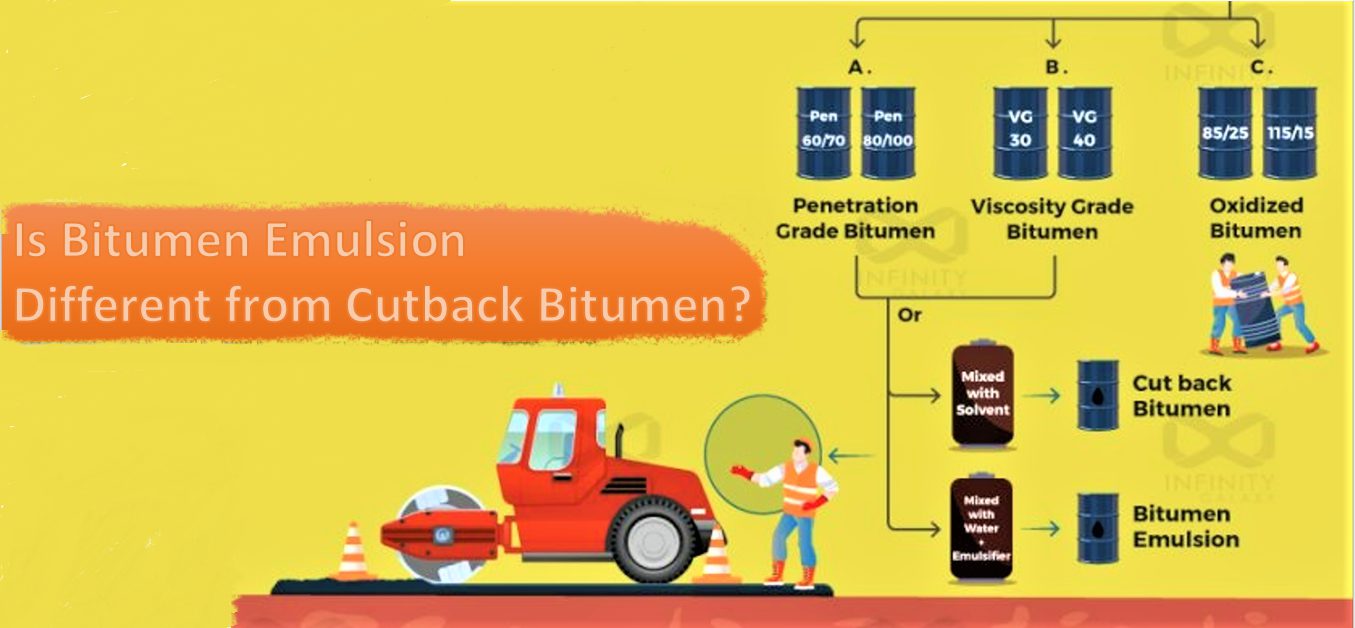

A short comparison between Bitumen, Cutback, and Emulsion

Bitumen should have been heated before application, to lower its viscosity rate.

Cutback bitumen offers some advantages over other types of bitumen. After the production of this low viscosity bitumen, the heating operation was put aside. Because the volatile solvents in cutback bitumen met the need for heating by alleviating its viscosity.

The only concern was the harm that cutback bitumen had, to the environment. The volatile solvents were noxious to nature, human and environment.

Then the Emulsifiers and Bitumen Emulsion came to the industry. Not only were they considered as in-noxious and safe materials since only water evaporated, but also they were energy efficient.

Must read: Advantages of bitumen emulsion to cut backs

Bitumen Slow Curing ( SC )

Cutback Bitumen Slow Curing, Sc is also known as road oil, is a residual substance which is obtained from the fractional distillation of specific crude petroleum. SC grades are 30, 70, 250, 800 and 3000 as follow:

| Cutback Bitumen Slow-Curing-30 Specifications | ||||

|---|---|---|---|---|

| Properties | Specification Limit | Test Method | ||

| Min | Max | |||

| Kinematic viscosity at 60°c ,cST | 30 | 60 | ASTM D2170 | |

| Flash point(tag open cup), °C | 65 | – | ASTM D3143 | |

| Distillation test Distillate, volume per cent of total Distillate to 680°F (360°C) | ||||

| To 190 °C | – | – | ASTM D402 | |

| To 225 °C | – | – | ||

| To 260 °C | – | – | ||

| To 316 °C | 10 | 30 | ||

| Residue from Distillation to 60 °C | ||||

| Penetration 77°F (25°C) 100g, 5s mm | 50 | – | ASTM D5 | |

| Ductility 77°F (25°C) 5cm/min cm | 100 | – | ASTM D113 | |

| Solubility in trichloroethylene % | 100 | – | ASTM D2042 | |

| Water, percent volume | – | 0.2 | ASTM D95 | |

| Cutback Bitumen Slow-Curing-70 Specifications | ||||

|---|---|---|---|---|

| Properties | Specification Limit | Test Method | ||

| Min | Max | |||

| Kinematic viscosity at 60°c ,cST | 70 | 140 | ASTM D2170 | |

| Flash point(tag open cup), °C | 60 | – | ASTM D3143 | |

| Distillate Test | ||||

| Total distillate to 360 °C (680 °F), volume % | – | 35 | ASTM D402 | |

| Solubility in trichloroethylene % | 95 | – | ||

| Kinematic viscosity on distillation residue at 60 °C (140 °F) mm2 /s | 200 | 7000 | ||

| Asphalt Residue | ||||

| Residue of 100 penetration, % | 40 | – | ASTM D5 | |

| Ductility 77°F (25°C) 5cm/min cm | 50 | – | ASTM D113 | |

| Water, percent volume | – | 0.5 | ASTM D95 | |

| Cutback Bitumen Slow-Curing-250 Specifications | ||||

|---|---|---|---|---|

| Properties | Specification Limit | Test Method | ||

| Min | Max | |||

| Kinematic viscosity at 60°c ,cST | 250 | 500 | ASTM D2170 | |

| Flash point(tag open cup), °C | 60 | – | ASTM D3143 | |

| Distillate Test | ||||

| Total distillate to 360 °C (680 °F), volume % | – | 25 | ASTM D402 | |

| Solubility in trichloroethylene % | 95 | – | ||

| Kinematic viscosity on distillation residue at 60 °C (140 °F) mm2 /s | 400 | 10000 | ||

| Asphalt Residue | ||||

| Residue of 100 penetration, % | 50 | – | ASTM D5 | |

| Ductility 77°F (25°C) 5cm/min cm | 50 | – | ASTM D113 | |

| Water, percent volume | – | 0.5 | ASTM D95 | |

| Cutback Bitumen Slow-Curing-800 Specifications | ||||

|---|---|---|---|---|

| Properties | Specification Limit | Test Method | ||

| Min | Max | |||

| Kinematic viscosity at 60°c ,cST | 800 | 1600 | ASTM D2170 | |

| Flash point(tag open cup), °C | 70 | – | ASTM D3143 | |

| Distillate Test | ||||

| Total distillate to 360 °C (680 °F), volume % | – | 15 | ASTM D402 | |

| Solubility in trichloroethylene % | 95 | – | ||

| Kinematic viscosity on distillation residue at 60 °C (140 °F) mm2 /s | 1000 | 16000 | ||

| Asphalt Residue | ||||

| Residue of 100 penetration, % | 60 | – | ASTM D5 | |

| Ductility 77°F (25°C) 5cm/min cm | 50 | – | ASTM D113 | |

| Water, percent volume | – | 0.5 | ASTM D95 | |

| Cutback Bitumen Slow-Curing-3000 Specifications | ||||

|---|---|---|---|---|

| Properties | Specification Limit | Test Method | ||

| Min | Max | |||

| Kinematic viscosity at 60°c ,cST | 3000 | 6000 | ASTM D2170 | |

| Flash point(tag open cup), °C | 70 | – | ASTM D3143 | |

| Distillate Test | ||||

| Total distillate to 360 °C (680 °F), volume % | – | 8 | ASTM D402 | |

| Solubility in trichloroethylene % | 95 | – | ||

| Kinematic viscosity on distillation residue at 60 °C (140 °F) mm2 /s | 2000 | 35000 | ||

| Asphalt Residue | ||||

| Residue of 100 penetration, % | 75 | – | ASTM D5 | |

| Ductility 77°F (25°C) 5cm/min cm | 50 | – | ASTM D113 | |

| Water, percent volume | – | 0.5 | ASTM D95 | |

Bitumen Medium Curing ( MC )

Cutback bitumen medium curing, MC, is a chemical combination of asphalt cement and petroleum solvent.

MC bitumen is widely used in tack coats, fog seals, slurry seals, and stabilizers. Mc grades have a high prioritized place in the Kenya market.

This bitumen grade is widely applied in many countries, especially East African countries such as Kenya and Tanzania.

Infinity Galaxy has successfully exported MC30 cutback bitumen and other MC grades monthly to eminent customers of these countries.

Are you looking for a bitumen supplier in Kenya? Click on Bitumen Supplier in Kenya to find out more.

Important to say that, exporting MC30 to Mombasa port of Kenya necessitates having PVOC (Pre-Export Verification of Conformity) and GIS (Government and Institution Services) documents, and the drums specific marking approved by Mombasa customs. On the contrary, for the export to other East African countries, PVOC and GIS are not required. Only the SGS inspection report is sufficient for the goods entrance.

To know more information about export documents click here.

Infinity Galaxy supplies Bitumen MC Grades in drums with 10 mm thickness to prevent any leakage. MC grades are as follow:

| Cutback Bitumen Medium-Curing-30 Specifications | ||||

|---|---|---|---|---|

| Properties | Specification Limit | Test Method | ||

| Min | Max | |||

| Kinematic Viscosity at 60 °C ,cSt | 30 | 60 | ASTM D2170 | |

| Flash Point (Top Open Cup), °C | 38 | – | ASTM D3143 | |

| Water Content (% Vol) | – | 0.2 | ASTM D95 | |

| Distillate, %Volume of Total Distillate to @360 °C | ||||

| To 225 °C | – | 25 | ASTM D402 | |

| To 260 °C | 40 | 75 | ||

| To 316 °C | 75 | 93 | ||

| Residue From Distillation to 360 °C (% Vol by Difference) | 50 | – | ||

| Penetration, 25 °C, (dmm) | 120 | 300 | ASTM D5 | |

| Ductility, 25 °C, (cm) | 100 | – | ASTM D113 | |

| Cutback Bitumen Medium-Curing-70 Specifications | ||||

|---|---|---|---|---|

| Properties | Specification Limit | Test Method | ||

| Min | Max | |||

| Kinematic Viscosity at 60 °C , mm2/s | 70 | 140 | ASTM D2170 | |

| Flash Point (Tag Open Cup), °C | 38 | – | ASTM D3143 | |

| Distillate, %Volume of Total Distillate to @360 °C | ||||

| To 225 °C | – | 25 | ASTM D402 | |

| To 260 °C | 10 | 70 | ASTM D402 | |

| To 316 °C | 75 | 93 | ASTM D402 | |

| Residue From Distillation to 360 °C (% Vol by Difference) | 55 | – | ASTM D402 | |

| Test On Residue from Distillation: | ||||

| Penetration, 25 °C, (dmm) | 120 | 300 | ASTM D5 | |

| Ductility, 25 °C, (cm) | 100 | – | ASTM D113 | |

| Solubility in Trichloroethylene, % | 99 | – | ASTM D2042 | |

| Water , % | – | 0.2 | ASTM D95 | |

| Cutback Bitumen Slow-Curing-250 Specifications | ||||

|---|---|---|---|---|

| Properties | Specification Limit | Test Method | ||

| Min | Max | |||

| Kinematic viscosity at 60°c ,cST | 250 | 500 | ASTM D2170 | |

| Flash point(tag open cup), °C | 60 | – | ASTM D3143 | |

| Distillate Test | ||||

| Total distillate to 360 °C (680 °F), volume % | – | 25 | ASTM D402 | |

| Solubility in trichloroethylene % | 95 | – | ||

| Kinematic viscosity on distillation residue at 60 °C (140 °F) mm2 /s | 400 | 10000 | ||

| Asphalt Residue | ||||

| Residue of 100 penetration, % | 50 | – | ASTM D5 | |

| Ductility 77°F (25°C) 5cm/min cm | 50 | – | ASTM D113 | |

| Water, percent volume | – | 0.5 | ASTM D95 | |

| Cutback Bitumen Medium-Curing-800 Specifications | ||||

|---|---|---|---|---|

| Properties | Specification Limit | Test Method | ||

| Min | Max | |||

| Kinematic viscosity at 60°c ,cST | 800 | 1600 | ASTM D2170 | |

| Flash point(tag open cup), °C | 66 | – | ASTM D3143 | |

| Distillation test Distillate, volume per cent of total Distillate to 680°F (360°C) | ||||

| Residue from distillation to 437°F (225°C) | – | – | ASTM D402 | |

| to 500°F (260°C) | – | 40 | ||

| to 600°F (316°C) | 45 | 90 | ||

| to 680°F (360°C), per cent volume by difference | 75 | – | ||

| Test on residue from distillation test | ||||

| Viscosity at 140°F (60°C) | 30 | 120 | ASTM D2170 | |

| Penetration 77°F (25°C) 100g, 5s mm | 120 | 250 | ASTM D5 | |

| Ductility 77°F (25°C) 5cm/min cm | 100 | – | ASTM D113 | |

| Solubility in trichloroethylene % | 99 | – | ASTM D2042 | |

| Water, percent volume | – | 0.2 | ASTM D95 | |

| Cutback Bitumen Medium-Curing-3000 Specifications | ||||

|---|---|---|---|---|

| Properties | Specification Limit | Test Method | ||

| Min | Max | |||

| Kinematic Viscosity at 60 °C , mm2/s | 3000 | 6000 | ASTM D2170 | |

| Flash Point (Tag Open Cup), °C | 66 | – | ASTM D3143 | |

| Distillate, %Volume of Total Distillate to @360 °C | ||||

| To 225 °C | – | – | ASTM D402 | |

| To 260 °C | – | 15 | ASTM D402 | |

| To 316 °C | 15 | 75 | ASTM D402 | |

| Residue From Distillation to 360 °C (% Vol by Difference) | 80 | 0 | ASTM D402 | |

| Test On Residue from Distillation: | ||||

| Viscosity at 60 °C | 30 | 120 | ASTM D2170 | |

| Penetration, 25 °C, (dmm) | 120 | 250 | ASTM D5 | |

| Ductility, 25 °C, (cm) | 100 | – | ASTM D113 | |

| Solubility in Trichloroethylene, % | 99 | – | ASTM D2042 | |

| Water , % | – | 0.2 | ASTM D95 | |

Bitumen Rapid Curing ( RC )

Cutback bitumen Rapid Curing, RC, is a petrochemical mixture of solvent as naphtha or gasoline and bitumen. RC grades are as come below:

| Cutback Bitumen Rapid-Curing-30 Specifications | ||||

|---|---|---|---|---|

| Properties | Specification Limit | Test Method | ||

| Min | Max | |||

| Kinematic viscosity at 60°c ,cST | 30 | 60 | ASTM D2170 | |

| Flash point(tag open cup), °C | – | – | ASTM D3143 | |

| Distillation test Distillate, volume per cent of total Distillate to 680°F (360°C) | ||||

| Residue from distillation to 437°F (225°C) | 55 | – | ASTM D402 | |

| to 500°F (260°C) | 75 | – | ||

| to 600°F (316°C) | 90 | – | ||

| to 680°F (360°C), per cent volume by difference | 50 | – | ||

| Test on residue from distillation test | ||||

| Penetration 77°F (25°C) 100g, 5s mm | 80 | 120 | ASTM D5 | |

| Ductility 77°F (25°C) 5cm/min cm | 100 | – | ASTM D113 | |

| Solubility in trichloroethylene % | 99 | – | ASTM D2042 | |

| Water, percent volume | – | 0.2 | ASTM D95 | |

| Cutback Bitumen Rapid-Curing-70 Specifications | ||||

|---|---|---|---|---|

| Properties | Specification Limit | Test Method | ||

| Min | Max | |||

| Kinematic viscosity at 60°c ,cST | 70 | 140 | ASTM D2170 | |

| Flash point(tag open cup), °C | – | – | ASTM D3143 | |

| Distillation test Distillate, volume per cent of total Distillate to 680°F (360°C) | ||||

| Residue from distillation to 437°F (225°C) | 50 | – | ASTM D402 | |

| to 500°F (260°C) | 70 | – | ||

| to 600°F (316°C) | 85 | – | ||

| to 680°F (360°C), per cent volume by difference | 55 | – | ||

| Test on residue from distillation test | ||||

| Penetration 77°F (25°C) 100g, 5s mm | 80 | 120 | ASTM D5 | |

| Ductility 77°F (25°C) 5cm/min cm | 100 | – | ASTM D113 | |

| Solubility in trichloroethylene % | 99 | – | ASTM D2042 | |

| Water, percent volume | – | 0.2 | ASTM D95 | |

| Cutback Bitumen Rapid-Curing-250 Specifications | ||||

|---|---|---|---|---|

| Properties | Specification Limit | Test Method | ||

| Min | Max | |||

| Kinematic viscosity at 60°c ,cST | 250 | 500 | ASTM D2170 | |

| Flash point(tag open cup), °C | – | – | ASTM D3143 | |

| Distillation test Distillate, volume per cent of total Distillate to 680°F (360°C) | ||||

| Residue from distillation to 437°F (225°C) | 35 | – | ASTM D402 | |

| to 500°F (260°C) | 60 | – | ||

| to 600°F (316°C) | 80 | – | ||

| to 680°F (360°C), per cent volume by difference | 65 | – | ||

| Test on residue from distillation test | ||||

| Penetration 77°F (25°C) 100g, 5s mm | 80 | 120 | ASTM D5 | |

| Ductility 77°F (25°C) 5cm/min cm | 100 | – | ASTM D113 | |

| Solubility in trichloroethylene % | 99 | – | ASTM D2042 | |

| Water, percent volume | – | 0.2 | ASTM D95 | |

| Cutback Bitumen Rapid-Curing-800 Specifications | ||||

|---|---|---|---|---|

| Properties | Specification Limit | Test Method | ||

| Min | Max | |||

| Kinematic viscosity at 60°c ,cST | 800 | 1600 | ASTM D2170 | |

| Flash point(tag open cup), °C | – | – | ASTM D3143 | |

| Distillation test Distillate, volume per cent of total Distillate to 680°F (360°C) | ||||

| Residue from distillation to 437°F (225°C) | 15 | – | ASTM D402 | |

| to 500°F (260°C) | 45 | – | ||

| to 600°F (316°C) | 75 | – | ||

| to 680°F (360°C), per cent volume by difference | 75 | – | ||

| Test on residue from distillation test | ||||

| Penetration 77°F (25°C) 100g, 5s mm | 80 | 120 | ASTM D5 | |

| Ductility 77°F (25°C) 5cm/min cm | 100 | – | ASTM D113 | |

| Solubility in trichloroethylene % | 99 | – | ASTM D2042 | |

| Water, percent volume | – | 0.2 | ASTM D95 | |

| Cutback Bitumen Rapid-Curing-3000 Specifications | ||||

|---|---|---|---|---|

| Properties | Specification Limit | Test Method | ||

| Min | Max | |||

| Kinematic viscosity at 60°c ,cST | 3000 | 6000 | ASTM D2170 | |

| Flash point(tag open cup), °C | – | – | ASTM D3143 | |

| Distillation test Distillate, volume per cent of total Distillate to 680°F (360°C) | ||||

| Residue from distillation to 437°F (225°C) | – | – | ASTM D402 | |

| to 500°F (260°C) | 25 | – | ||

| to 600°F (316°C) | 70 | – | ||

| to 680°F (360°C), per cent volume by difference | 80 | – | ||

| Test on residue from distillation test | ||||

| Penetration 77°F (25°C) 100g, 5s mm | 80 | 120 | ASTM D5 | |

| Ductility 77°F (25°C) 5cm/min cm | 100 | – | ASTM D113 | |

| Solubility in trichloroethylene % | 99 | – | ASTM D2042 | |

| Water, percent volume | – | 0.2 | ASTM D95 | |